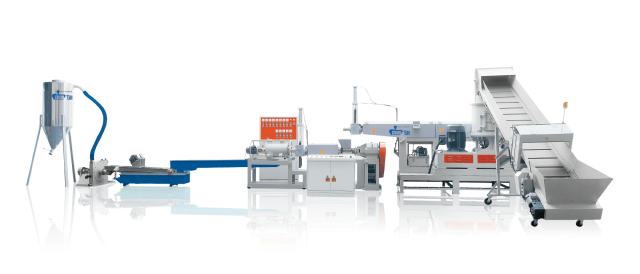

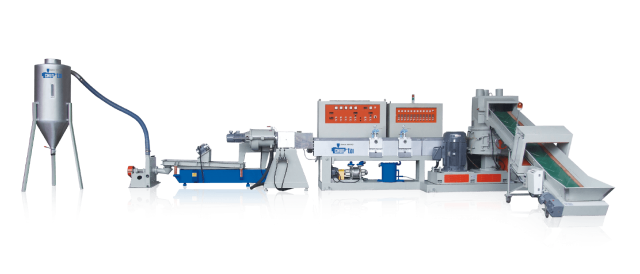

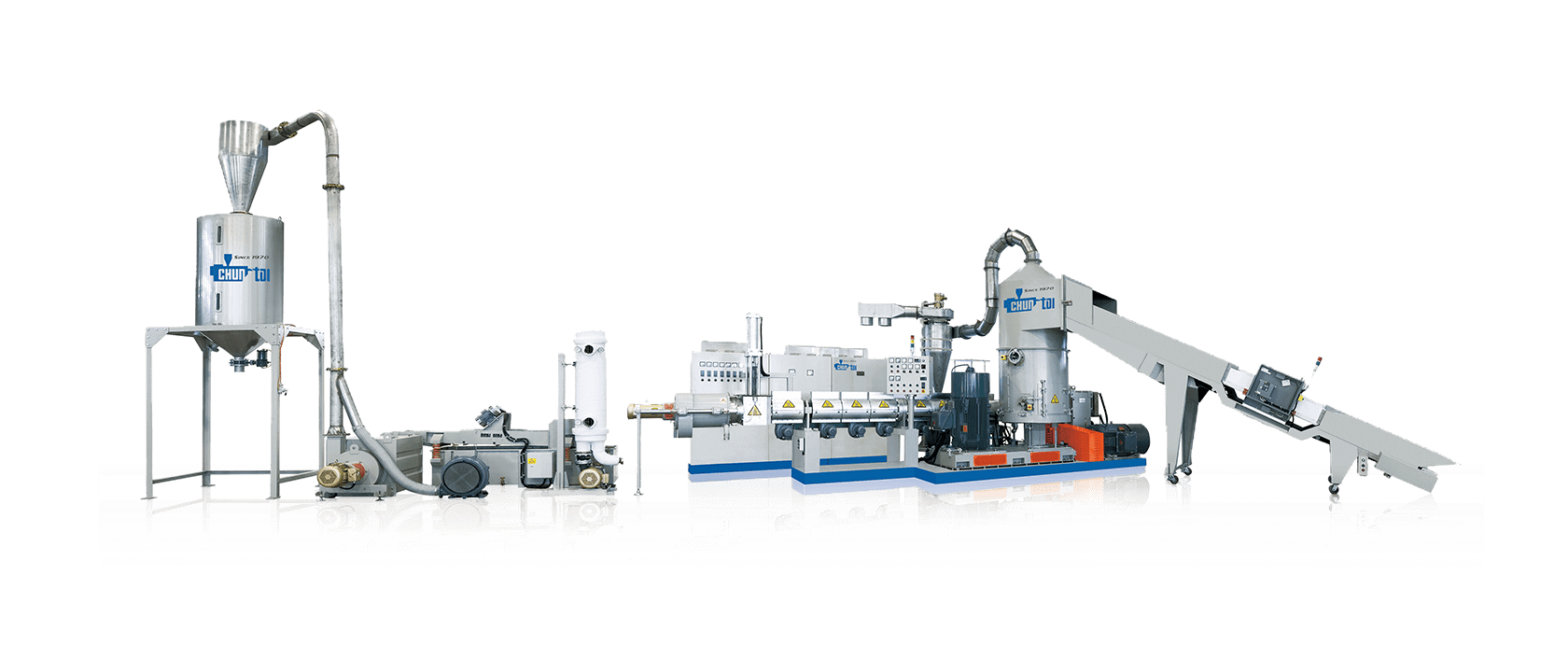

Plastic Film Recycling Machine (Die-face Cutting)

Is this 3-in-1 Film Recycling Extruder suitable for your recycling needs?

If you are facing these issues

- Light and soft films feed unevenly and require frequent manual intervention

- High knife wear and noise increase maintenance and operating burden

- Separated processes require more labor and limit overall throughput

How Chun Tai Helps

- 3-in-1 integrated design stabilizes the film recycling process

- Die-face pelletizing reduces knife usage and operating noise

- Less manual handling helps increase overall recycling output

Design Concept & Positioning

This system is developed to address common challenges in thin film recycling, such as unstable feeding, high manual involvement, and excessive knife wear. By integrating crushing, extrusion, and die-face pelletizing into a single process, film waste can be recycled and pelletized under controlled and stable conditions. The die-face pelletizing method helps minimize blade usage and maintenance requirements, while reducing operating noise. The machine supports common film materials such as PE, PP, and PS, and is positioned for recycling facilities seeking a practical, long-term solution for continuous thin film recycling operations.

Key Design Features

-

High-Efficiency Recycling:

Uses advanced single screw extrusion technology to recycle plastic films efficiently and produce high-quality recycled pellets.

-

Energy Saving and Environmental Compliance:

Designed to reduce blade wear, lower reliance on manual labor, and decrease noise output. Complies with environmental standards and supports plastic waste reduction.

-

Easy Operation:

Equipped with intuitive controls that are easy to operate, requiring minimal manual intervention.

-

Wide Material Compatibility:

Capable of processing various film materials such as PE, PP, and PS. Suitable for different types of film recycling applications.

Industries & Applications

-

Handles edge trims, film waste, and production rejects to improve yield and reduce material loss.

-

Reprocesses reclaimed sheets for reuse in construction, packaging, and other plastic product applications.

-

Provides a stable output of recycled pellets for high-volume production.

-

Produces quality recycled pellets through integrated recycling and pelletizing processes to support circular economy practices.

Specifications

| Item | Specification |

|---|---|

| Applicable Materials | HDPE, LDPE, LLDPE, BOPP; suitable for mono- and multi-layer plastic films |

| Capacity Range | Approx. 100–1500 kg/hr |

| Extruder Type | Single screw extruder |

| Pelletizing Options | Die-face hot cutting and strand pelletizing supported |

| Feeding System | Compatible with automatic feeding systems (configuration based on material type) |

| Power Requirement | Configured based on plant voltage (V, Hz, kW) |

| Machine Dimensions | Approx. 12m × 5m × 3m |

FAQ

It can process HDPE, LDPE, LLDPE, and BOPP films, including both mono-layer and multi-layer types.

No. The machine can process materials directly without a separate crusher.

The choice depends on the material characteristics. Please contact our technical team for further guidance.

Yes, it can.

This model is designed for stand-alone use and is not configured for full-line automation.