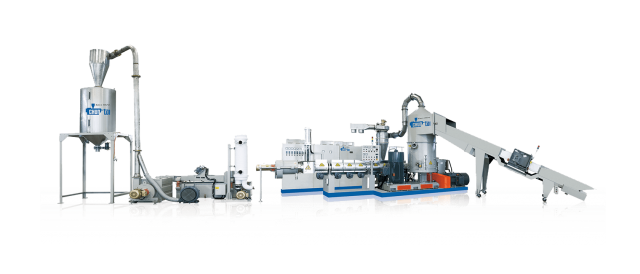

Squeezing Pelletizer

Product Overview

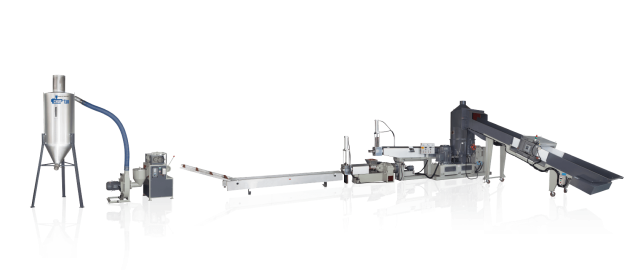

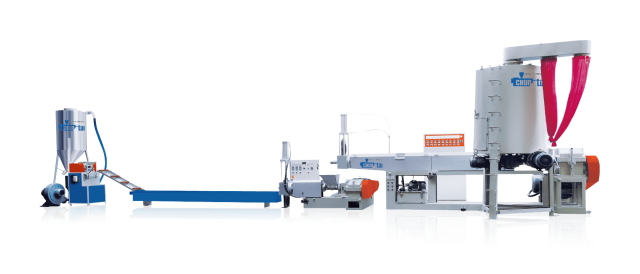

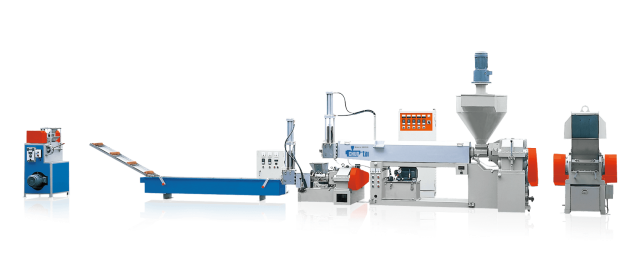

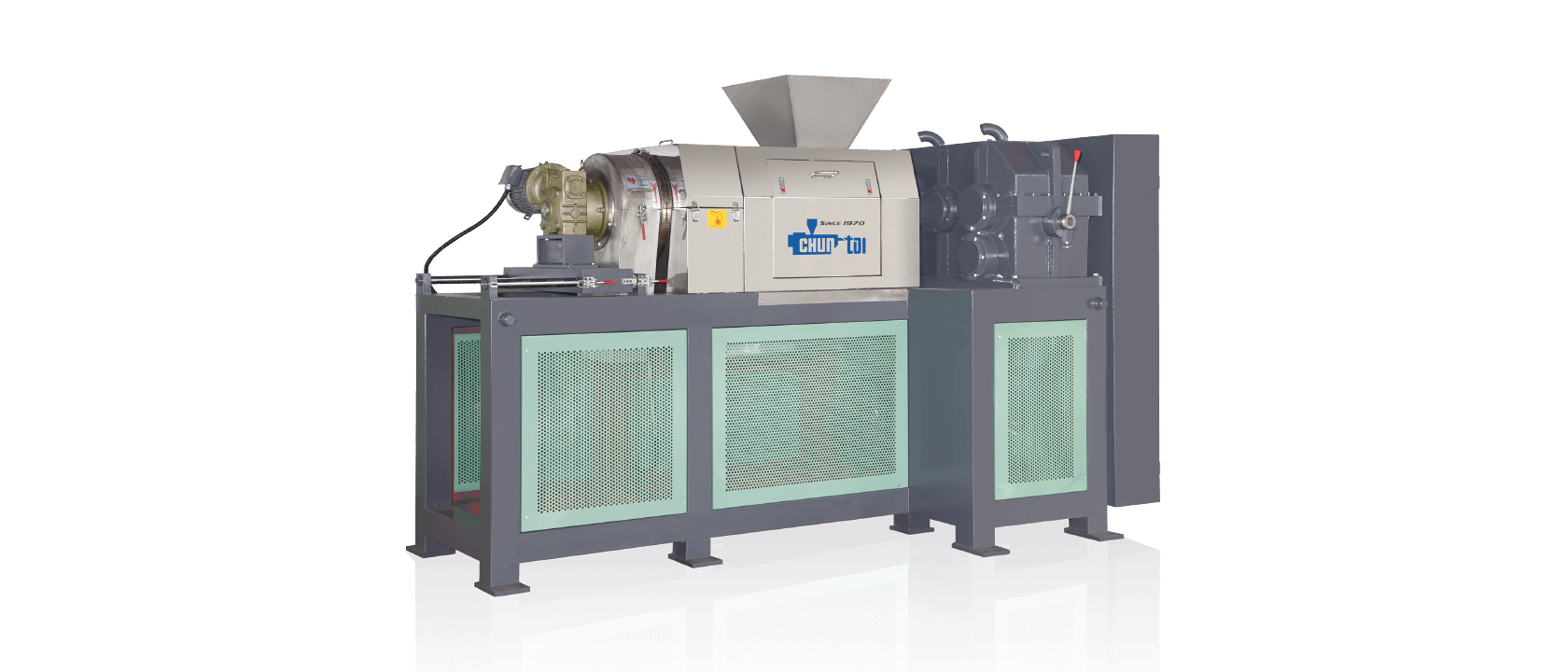

The Squeezing Pelletizer is an integrated system that combines dewatering and pelletizing in a single, space-saving unit. Designed for processing washed PE/PP film scrap, it compresses, dries, and pelletizes the material in one continuous process. Moisture is reduced to ultra-low levels, and pellet size can be precisely adjusted through interchangeable die heads and customizable cut lengths.

With a modular design featuring an independent pelletizing motor and stainless steel contact surfaces, the machine offers outstanding flexibility and durability. It is ideally suited for high-efficiency, high-throughput recycling lines that prioritize automation and energy savings.

Key Features

- Integrated Dewatering & Pelletizing: Combines moisture removal and pellet formation into a single, streamlined operation.

- Customizable Pellet Size: Pellet length and die head configuration can be tailored to specific product requirements.

- Independent Pelletizing Motor: Enables precise control over cut length and cutting speed for consistent pellet quality.

- Stainless Steel Contact Surfaces: Provides corrosion resistance, long-term durability, and easy maintenance.

- Adaptable to Varying Feed Conditions: Effectively handles film with different moisture levels and thickness variations.

- Automation-Ready Design: Easily integrates into washing lines and automated feeding/discharge systems.

Applications

- Pelletizing of soft plastic films such as PE and PP

- Direct downstream processing following film washing lines

- High-efficiency drying and customized pellet production in recycling plants

Technical Specifications

| Item | Specification |

|---|---|

| Capacity | Approx. 600 kg/hr |

| Recommended Feed Moisture | Suitable for washed film with medium to high moisture content |

| Dewatering Performance | Removes up to 100% of free water; residual moisture is extrusion-ready |

| Pellet Size Adjustment | Adjustable die heads and cut length |

| Pelletizing Drive | Independently driven motor for precise cutting control |

| Contact Material | Stainless steel (food-grade corrosion resistance and easy cleaning) |

| Blade Maintenance | Replacement frequency depends on material type and usage conditions |

| Line Integration | Compatible with film washing and automated feeding systems |

| Material Compatibility | Processes various film types across different moisture levels and thicknesses |

FAQ

- Q1: Does the machine handle both dewatering and pelletizing?

A1: Yes. It combines squeezing and pelletizing functions in one unit, saving space and minimizing drying time. - Q2: Is pellet size adjustable?

A2: Yes. Both the cut length and die heads can be customized to meet your specific product requirements. - Q3: Can it process high-moisture film scrap?

A3: Absolutely. It is designed to handle washed film with moderate to high moisture levels. - Q4: Can the machine be connected to an existing washing line?

A4: Yes. It easily integrates with film washing lines and supports automated feeding and discharge. - Q5: What materials are used in the contact surfaces? Are they easy to clean?

A5: All contact parts are made from stainless steel for superior corrosion resistance and easy cleaning.

Related Products