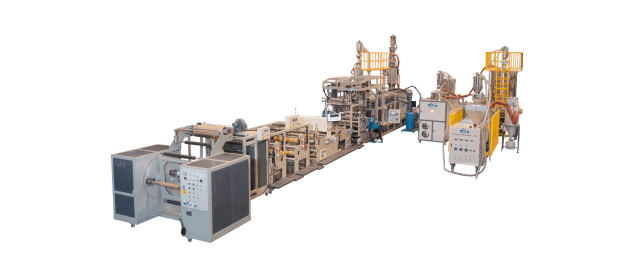

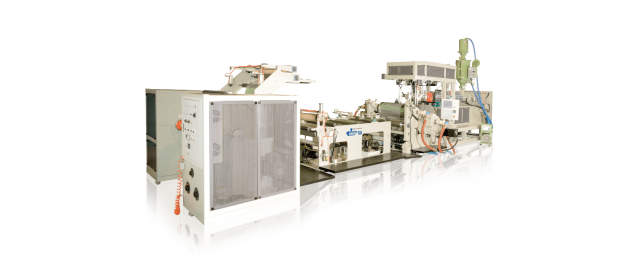

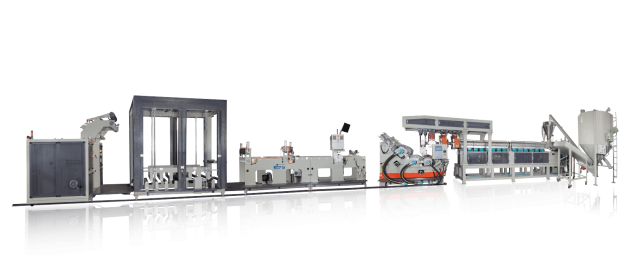

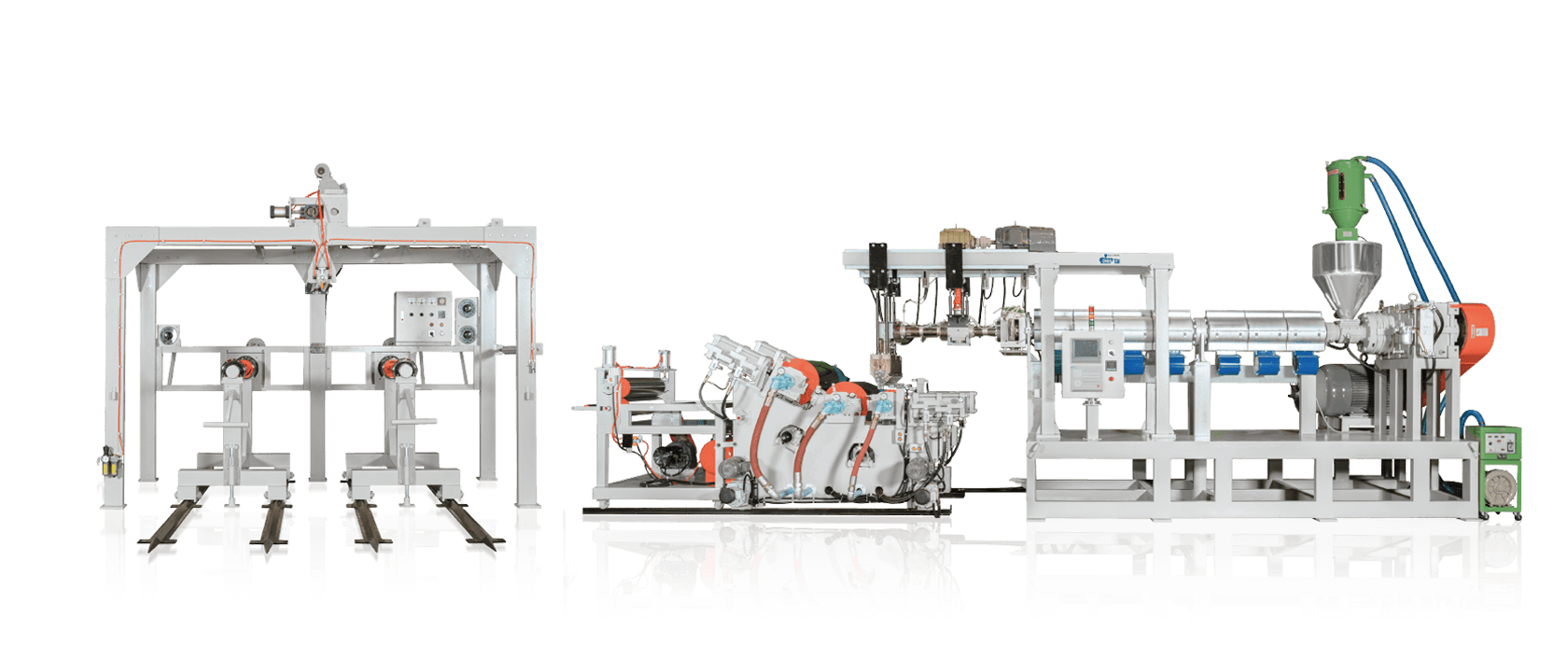

HIPS Sheet Extruder

Is this HIPS sheet extrusion line suitable for your production needs?

If you are facing these issues

- Sheet thickness is inconsistent

- Extended setup time when switching between product specifications

- Stable at low output, but instability occurs at higher production rates

How CHUN TAI helps

- Consistent sheet thickness across batches

- Faster stabilization when switching products

- Stable operation even at higher output levels

Design Concept & Positioning

It is suitable for applications in electronics packaging, medical device packaging, and home appliance components. The machine delivers consistent sheet thickness and reliable output to meet industry standards. Whether for small batches or large-scale production, this extruder provides a dependable and scalable solution.

Key Design Features

-

High Throughput:

Designed for efficient production, with output capacities of several hundred kilograms per hour. Adaptable to different production scales.

-

Adjustable Thickness Range:

Produces HIPS sheets from 0.2 mm to 5 mm to meet a variety of application needs.

-

Wide Sheet Width:

Supports extrusion widths up to 1600 mm for wide-format sheet production.

-

Advanced Control System:

Equipped with a PLC system that provides accurate temperature control and adjustable sheet thickness to ensure consistent quality.

-

Energy Efficiency:

Includes energy-saving features such as inverters and servo motors to reduce power consumption and support efficient operation.

-

Modular and Maintainable Design:

The machine features a modular structure for easy maintenance and optional configuration adjustments based on production requirements.

Industries & Applications

-

Produces plastic cups, lunch boxes, trays, takeaway containers, and microwave-safe food packaging.

-

Suitable for manufacturing lightweight, rigid HIPS spoons, bowls, and beverage lids.

-

Used for forming impact-resistant plates, bowls, and containers with stable dimensions.

-

Applies to disposable medical trays, protective covers, and lightweight packaging for hygiene-related products.

Specifications

| Item | Specification |

|---|---|

| Application Type | HIPS sheet production; supports single-layer and up to 3-layer co-extrusion |

| Extrusion Technology | Single screw system with main/sub extruder configuration |

| Applicable Materials | HIPS only; compatible with virgin and recycled materials (ABS not supported) |

| Sheet Thickness Range | 0.2–1 mm |

| Sheet Width Range | Customizable die widths based on production needs |

| Layer Configuration | Supports up to 3-layer co-extrusion |

| Production Capacity | Approx. 200–800 kg/hr |

| Control System | PLC with HMI and automatic temperature control |

| Power Requirement | Configured based on plant voltage (V, Hz, kW) |

| Additional Features | Optional edge trim recycling; automatic screen and die changers not included |

FAQ

Yes. The sheets produced are suitable for downstream vacuum forming and thermoforming.

Yes. The machine supports the use of recycled HIPS materials.

No. These features are not included in the standard configuration.

Yes. Both the die width and layer structure can be configured according to customer requirements.