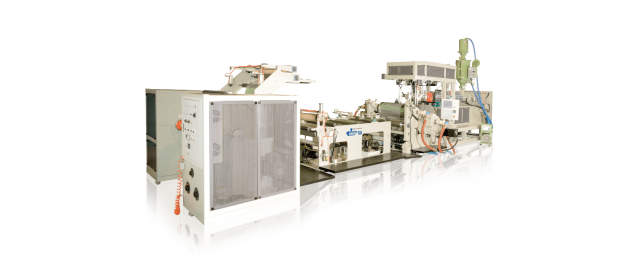

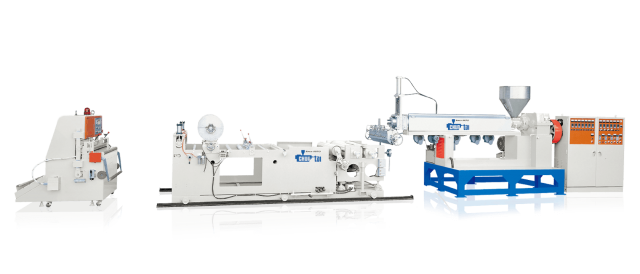

Microcomputer Slicer

Product Overview

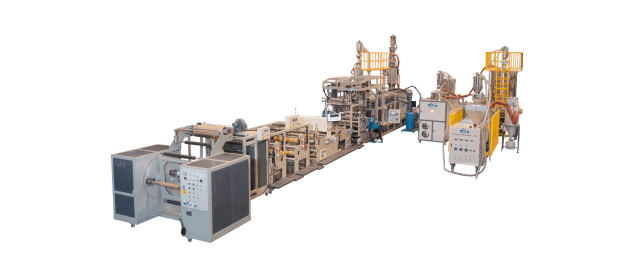

The Microcomputer Slicer is designed for precision cutting of rigid plastic sheets and is widely used in applications such as electronic films, stationery pads, and secondary processing of extruded sheets. It supports inline integration with extruders or winding systems and features automatic feeding and cutting to improve production efficiency and dimensional accuracy in mass production.

This machine is suitable for both domestic and international markets, commonly used in electronics component processing, plastic stationery manufacturing, and sheet cutting service industries.

Key Features

- Versatile Material Compatibility

Capable of cutting various plastic sheets, including PP, PET, PVC, PC, ABS, and HIPS. - Supports up to 5 mm Thickness

Handles rigid sheet materials with a maximum cutting thickness of 5 mm. - Easily Adjustable Length and Quantity

Cutting length and batch quantity (up to 3000 sheets per job) can be quickly set for efficient production. - Automatic Feeding & Stacking

Reduces manual labor with automated material feeding and finished sheet collection. - User-Friendly Control Interface

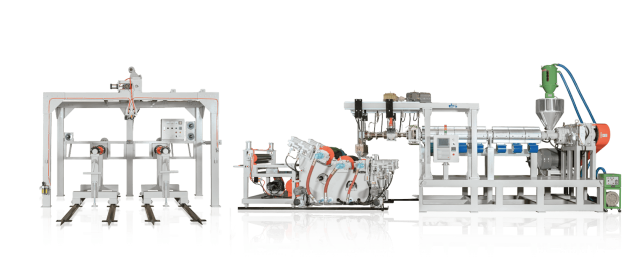

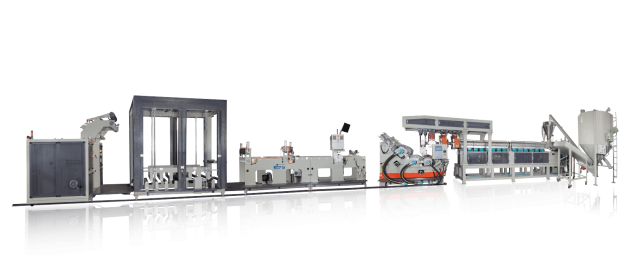

Equipped with a PLC and HMI touchscreen for simple operation and fast setup. - Inline Integration Ready

Compatible with extrusion and winding systems for inline automated workflows.

Technical Specifications

| Item | Specification |

|---|---|

| Application Type | For cutting plastic sheets, stationery backing boards, and electronic film materials |

| Compatible Materials | PP, PET, PVC, PC, ABS, HIPS |

| Max Cutting Thickness | 5 mm |

| Control System | PLC with HMI touchscreen interface |

| Drive System | Hydraulic-powered cutting blade; stepper motor-driven feeding system |

| Connectivity | Supports inline connection with extrusion or winding systems |

| Power Requirement | Configured based on plant voltage (V, Hz, kW) |

| Machine Dimensions | Approx. 1.8m × 1.5m × 2m |

FAQ

- Q1: Can this machine cut various plastic materials? What is the maximum thickness?

A: Yes, it supports multiple plastic sheet types with a maximum cutting thickness of 5 mm. - Q2: Can this machine be integrated with an extrusion line or other automation equipment?

A: Yes, it supports inline connection with extruders or winding systems for automated production. - Q3: Does the control panel include recipe memory and multilingual support?

A: Recipe memory is not included, but multilingual interface support is available.