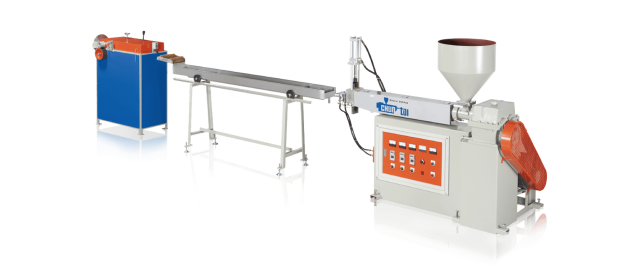

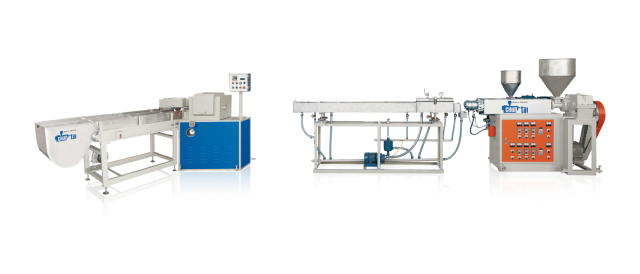

PP Packing Belt Making Machine

Product Overview

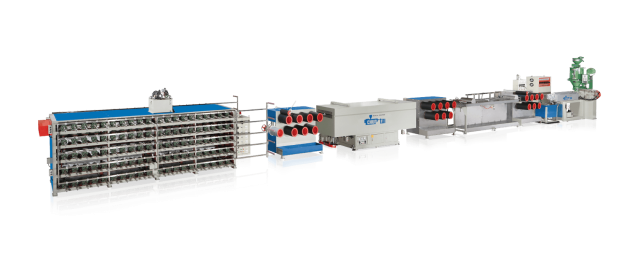

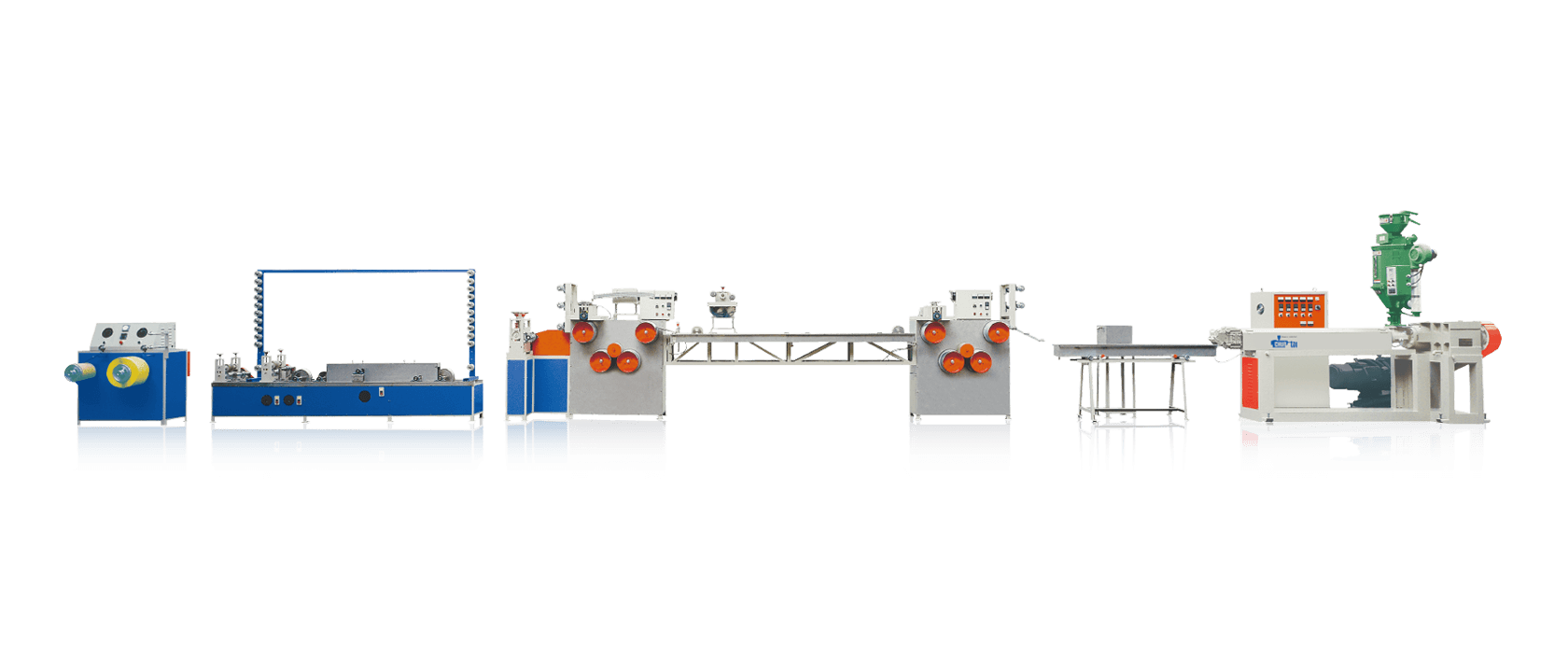

This advanced extrusion system is designed for the high-efficiency production of PP strapping belts used in a wide range of packaging applications. Suitable for both manual strapping tools and high-speed automatic machines, the line supports customizable belt widths, thicknesses, and surface textures—including smooth or embossed finishes. Optional features such as inline inkjet printing and dual-color co-extrusion further enhance brand visibility and product traceability. Built to accommodate both virgin and recycled PP, the system ensures consistent quality with minimal downtime thanks to its fast-change tooling and stable tension control.

Key Features

- Customizable Belt Dimensions:

Tailor belt width and thickness to suit diverse packaging systems—from handheld tools to automated lines. - Smooth or Embossed Finishes:

Easily switch between surface textures using interchangeable embossing molds—ideal for branding or functional grip. - Inline Printing & Dual-Color Capability:

Optional inkjet module and co-extruder enable real-time labeling and two-tone production for enhanced product identity. - Recycled Material Compatible:

Supports blends with recycled PP while maintaining strength, offering a sustainable and cost-effective solution. - Rapid Size Changeover:

Adjust belt formats without recalibrating tension or disrupting the line, increasing uptime and flexibility.

Application Industries

- Logistics & Warehousing – Palletizing, bundle securing, warehouse inventory control

- Consumer Electronics & Appliances – Safe transport packaging for fragile goods

- Food & Beverage – Box strapping for bottled water, frozen food, shrink packaging

- General Manufacturing – Heavy-duty industrial packaging and export cargo securing

Technical Specifications

| Item | Description |

|---|---|

| Belt Width & Thickness | Fully customizable per application |

| Surface Finish | Smooth or embossed (mold change required) |

| Embossing Mold | Pattern and size can be customized |

| Roll Core Size | Adjustable; with tension control |

| Printing System | Optional inkjet system with customizable font and layout |

| Materials | Virgin PP and recycled PP blends |

| Tension Control | Maintains stability across sizes—no re-tuning needed |

| Speed Switching | Supports quick changeovers for different specs |

FAQ

- Q1: Can this system produce different belt widths and finishes?

A1: Yes, widths and surface textures can be changed quickly by swapping out the die and embossing mold. - Q2: Will recycled PP reduce product quality?

A2: When blended and filtered correctly, recycled PP delivers reliable performance with minimal impact on strength or appearance. - Q3: Is inline printing fully customizable?

A3: Absolutely. The optional inkjet module allows for adjustable fonts, layouts, and multi-line printing to support traceability or branding. - Q4: Can this line integrate with automated winding or packaging systems?

A4: Yes, it can be configured to work seamlessly with automatic take-up units or downstream packaging lines, depending on your workflow.