Infrared Crystallizer Dryer

High-Speed Infrared Crystallizer Dryer for PET/PLA Materials

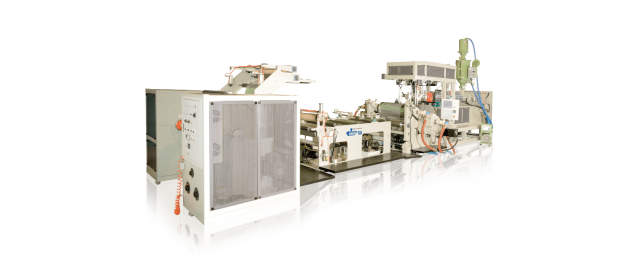

Product Overview

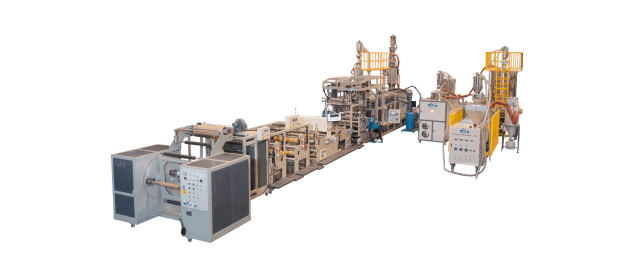

The Infrared Crystallizer Dryer is engineered for drying and crystallizing crystalline polymers such as PET, RPET, and PLA. By combining far-infrared heating and crystallization in a single compact system, it is especially suited for preparing recycled materials with high initial moisture content.

A high-speed rotating drum paired with far-infrared radiation enables rapid moisture reduction, bringing final moisture levels down to 50–100 PPM. This ensures stable performance in downstream extrusion, thermoforming, or blow molding processes.

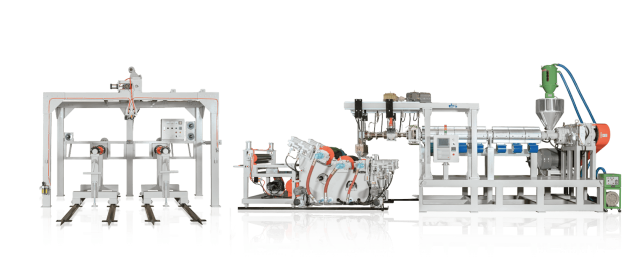

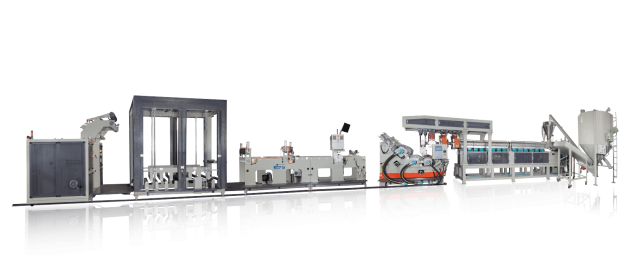

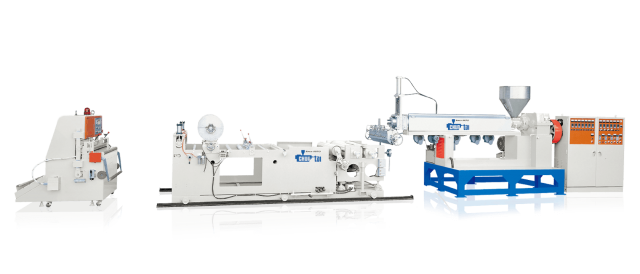

The system can operate as a stand-alone unit or be integrated into a complete processing line. Optional modules—including auto-feeding, dust removal, and contaminant separation—are available to meet diverse plant layouts and production requirements.

Key Features

- Integrated Infrared Crystallizing & Drying: Combines infrared heating and crystallization into one unit for compact, energy-efficient operation.

- High-Efficiency Moisture Reduction: Reduces moisture content to 50–100 PPM, enabling reliable extrusion or molding results.

- Modular System Design: Supports optional modules such as auto-feeders, de-dusters, and contaminant separators.

- Scalable and Upgradeable: Modular configuration allows future expansion and adaptation to changing production needs.

- Optimized for Recycled PET: Processes clean recycled PET flakes to improve pre-treatment quality and reduce downstream failure risk.

Applications

- Drying and crystallizing PET, RPET, and PLA flakes or granules

- Pre-treatment for melt extrusion, sheet production, or blow molding

- Dehumidification and crystallization of recycled PET materials

- Can be integrated with auto-feeders, IR dehumidifiers, contaminant separators, and extrusion systems

Technical Specifications

| Item | Specification |

|---|---|

| Applicable Materials | PET, RPET, PLA (clean input only; not suitable for contaminated feedstock) |

| Final Moisture Level | 50–100 PPM |

| Operating Modes | Stand-alone drying or integrated crystallizing-drying system |

| Modular Expansion | Supports modules for dust removal, contaminant separation, and automatic feeding |

| System Integration | Compatible with extrusion lines; commonly used in PET and PLA processing facilities |