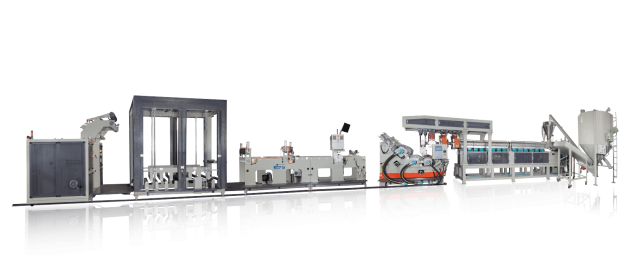

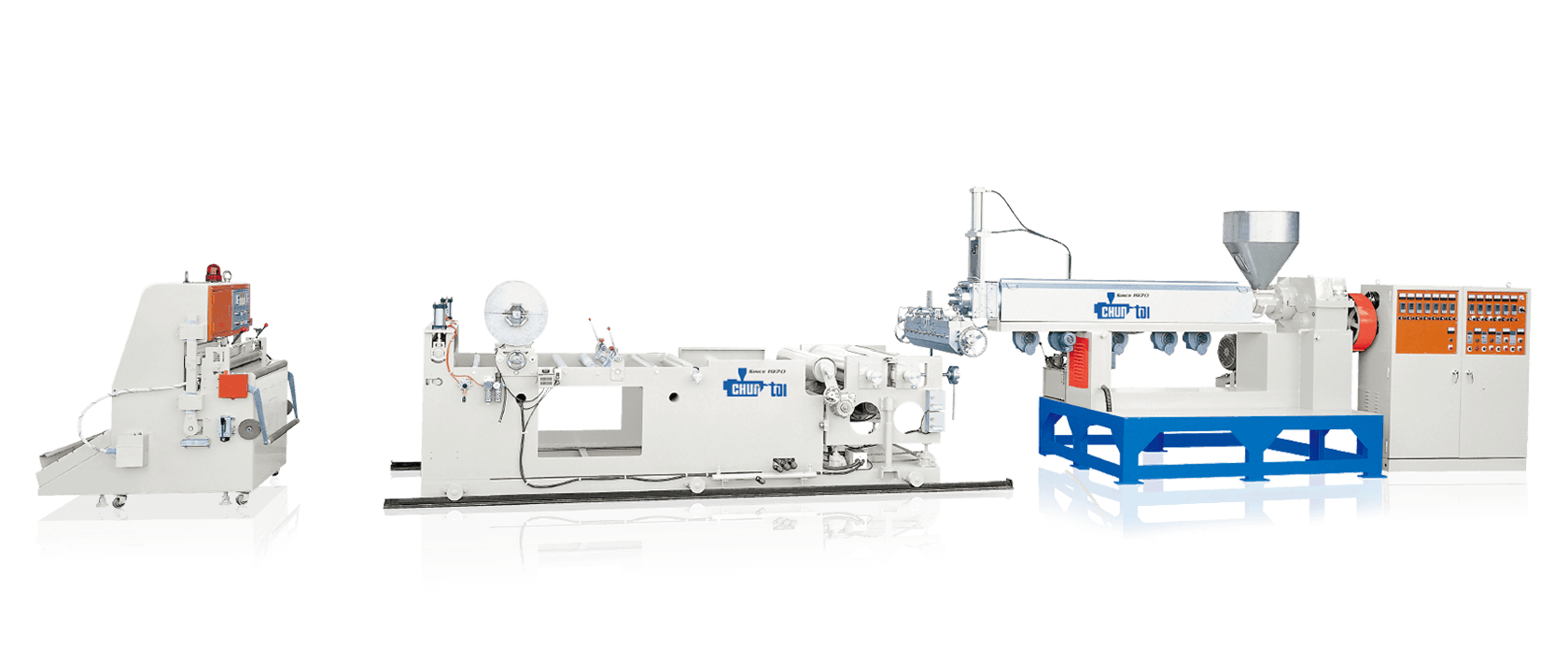

PP File Folder Sheet Extruder

Is the Chun Tai PP File Folder Sheet Extruder suitable for your production needs?

Common Production Issues

- Inconsistent sheet thickness affecting folder forming and handling feel

- Uneven embossing results causing visible differences between batches

- Inefficient changeover between roll and sheet production modes

How Chun Tai Addresses These Issues

- Extrusion and haul-off design focused on stable sheet thickness

- Compatible with different embossing rollers to maintain surface consistency

- Supports both roll and sheet output with adjustable line configuration

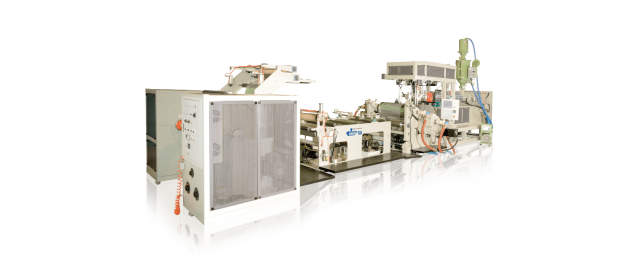

Design Concept & Positioning

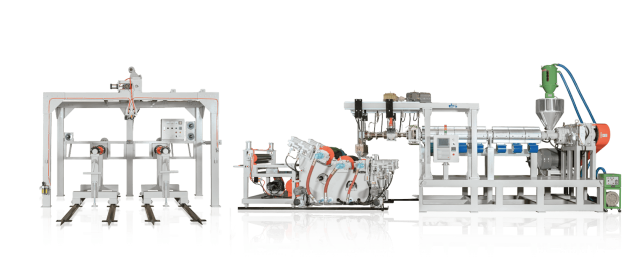

The PP File Folder Sheet Extruder is developed for producing polypropylene (PP) sheets used in stationery products such as file folders and document holders, leveraging PP’s durability and flexibility to support a wide range of thickness and application requirements. Optional embossing rollers, including diagonal, matte, and cross-hatch patterns, allow manufacturers to produce sheets with different surface finishes to meet market and product design needs. The line supports both roll and sheet output, and trimmed edges can be ground and recycled directly back into the production process, helping maintain stable operation and reduce material waste. The design focuses on production stability, flexible specification adjustment, and practical on-site operation, making it suitable for continuous mass production of stationery-grade PP sheets.

Key Design Features

-

High Extrusion Capacity:

Designed for efficient and scalable sheet production to meet various output requirements.

-

Adjustable Thickness:

Produces PP sheets with thicknesses from 0.2 mm to 3 mm, suitable for different folder specifications.

-

Wide Extrusion Width:

Supports sheet widths up to 1300 mm, compatible with most standard stationery sizes.

-

Precision Control:

Integrated PLC control system ensures accurate temperature and thickness control for stable, high-quality output.

-

Energy-Saving Design:

Utilizes inverters and servo motors to reduce power consumption and support energy-efficient production.

-

Modular Structure:

Easy to maintain and configurable for either cutting or rolling, depending on production requirements.

Industries & Applications

-

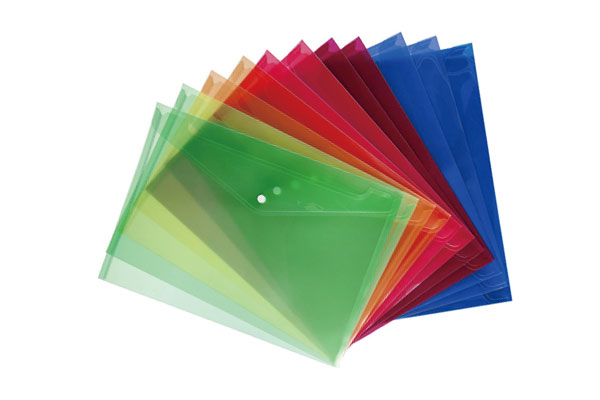

PP document folders, L-type folders, button folders, spring files.

-

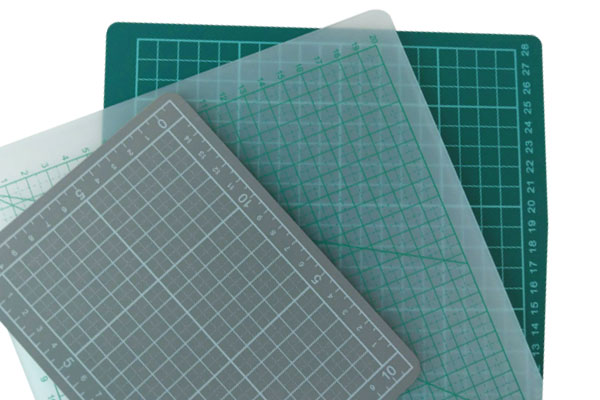

Colored backing boards, drawing pads, punching mats.

-

Cutting mats, crafting boards, labeling backers.

-

Presentation folders, report covers, branded display files.

Specifications

| Item | Specification |

|---|---|

| Application Type | For PP sheets used in stationery and school supply applications; supports both thin and thick sheet production |

| Extrusion Technology | Single screw extrusion; supports AB or ABA co-extrusion with main/sub extruders |

| Compatible Materials | PP only; compatible with virgin, recycled, or reprocessed materials |

| Sheet Thickness Range | 0.3–3 mm; adjustable based on product requirements |

| Sheet Width Range | Maximum width 1300 mm; not extendable beyond this limit |

| Embossing Options | Supports pattern rollers for diagonal, cross-hatch, and matte textures |

| Output Capacity | Approx. 200–500 kg/hr |

| Cooling System | Equipped with three horizontal calender rolls |

| Post-Processing Modes | Supports both cutting and rolling; includes dual-edge trim recycling |

| Power Requirement | Configured according to plant voltage (V, Hz, kW) |

| Machine Dimensions | Approx. 15m × 4m × 3m; installation space based on factory layout planning |

FAQ

Yes. Production mode can be switched flexibly as needed.

Yes. Recycled PP can be used. Pre-drying is recommended for moist materials.

Yes. The system allows quick roller changes and supports multiple embossing textures.

Yes. Width and cutting settings can be modified based on product specifications.

Yes. A dual-edge recycling system is standard.

No. Full-line integration is not available; each section must be planned separately.