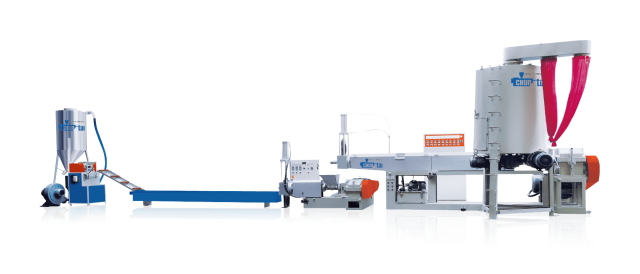

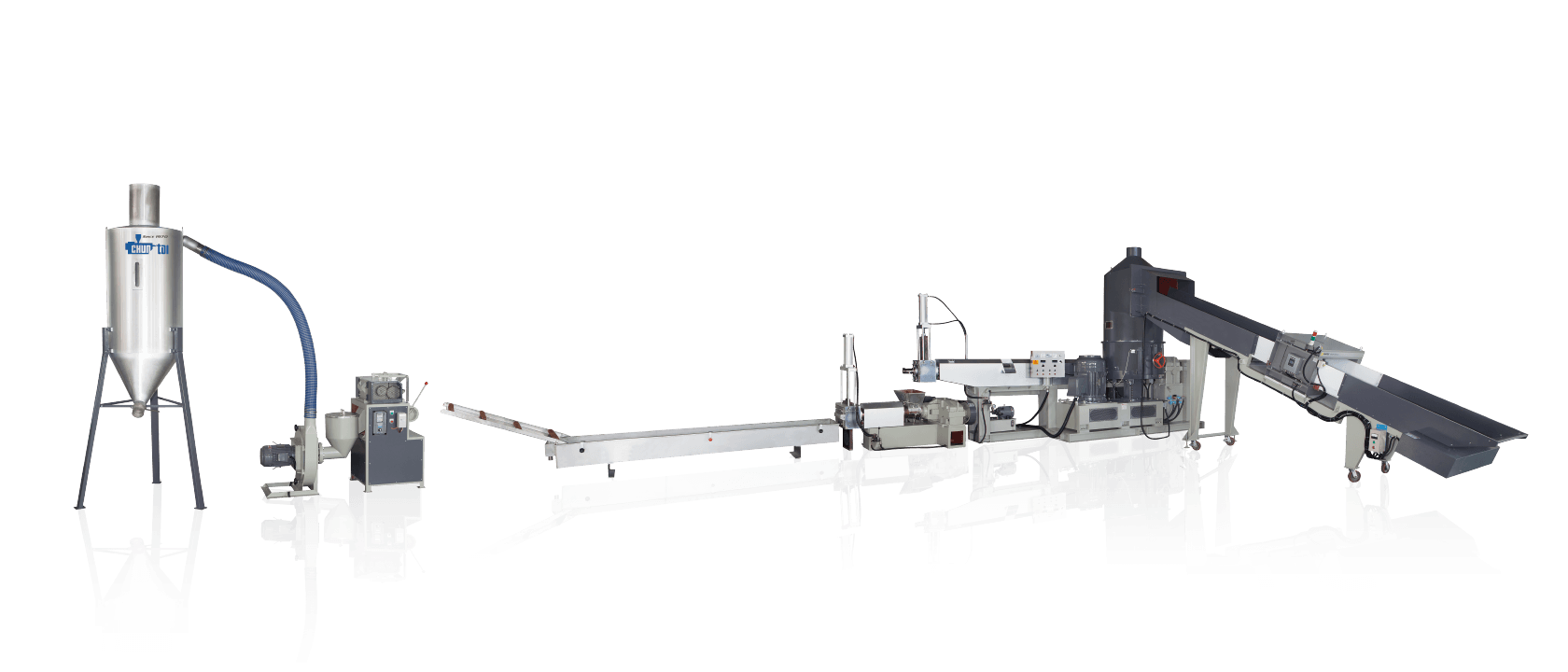

2 Stages Plastic Film Recycling Machine (Strand Cutting)

Product Overview

The 2-Stage Plastic Film Recycling Machine (Strand Cutting) is designed for efficient recycling of soft films and mixed-material plastic waste. Equipped with a tandem (mother-baby) two-stage extrusion system, it integrates shredding, extrusion, and strand pelletizing into a compact and streamlined configuration.

This system is particularly effective for processing flexible PE/PP films, woven bags, and printed films—especially those with high viscosity or unstable melt flow. It employs strand pelletizing with water bath cooling and air drying, ensuring steady output even for materials that are challenging to pelletize via die-face cutting.

With features such as a hydraulic quick screen changer, one-touch control, and optional modules including metal detectors and odor removal systems, the machine offers high configurability for a wide range of modern film recycling lines.

Key Features

- Tandem (Mother-Baby) Two-Stage Extrusion:

Engineered to process highly contaminated, high-viscosity, or mixed-material inputs with superior melt stability. - 3-in-1 Integrated System:

Combines shredding, extrusion, and strand cutting in one unit—reducing footprint, noise, and material handling. - Strand Cutting with Water Cooling & Air Drying:

Ideal for materials that are difficult to pelletize using die-face systems, offering stable pelletizing performance. - Hydraulic Quick Screen Change:

Speeds up filter replacement, reduces downtime, and supports smoother operation. - Modular Automation Add-Ons:

Supports the integration of metal detectors, vacuum pumps, odor control units, and post-processing storage systems. - Flexible L-Shaped Layout:

Fits production environments with linear line setups (not compatible with U-shaped configurations). - Recipe Memory & Automated Line Control:

Includes one-touch start/stop, recipe storage, safety interlocks, and metal detection alerts for standardized operation.

Applications

- Soft PE/PP films, woven sacks, and printed packaging film

- LDPE, LLDPE, HDPE, and other flexible packaging waste

- Washed, high-viscosity film scrap and mixed post-consumer plastics

- Unstable or hard-to-process recycled film materials

Technical Specifications

| Item | Specification |

|---|---|

| Processable Materials | LDPE, LLDPE, HDPE, PP soft films, printed film waste, and flexible packaging |

| Extrusion System | Tandem (mother-baby) two-stage extruders, L/D ratio approx. 28–33:1 (customizable) |

| Pelletizing Method | Strand cutting with water bath cooling and air drying |

| Integrated Workflow | Shredding, extrusion, and pelletizing in a single unit |

| Degassing & Filtration | Dual venting and dual filtration die head (customizable upon request) |

| Screen Change | Hydraulic quick-change system |

| Control Features | One-touch operation, recipe memory, metal contamination alerts |

| Optional Modules | Vacuum pump, metal detector, odor control unit, cooling loop, material storage (pellet cooling module not supported) |

| Layout Configuration | Supports L-shaped layout only |

| Pellet Drying | Air-dried strand pellets suitable for packaging or further feeding |

FAQ

Q1: What types of plastic waste can this machine process? Does it support woven bags and mixed materials?

A1: Yes. It is designed to handle soft PE/PP films, printed packaging, woven sacks, and post-consumer mixed plastic film waste.

Q2: Does it use a two-stage extrusion system? What are the benefits?

A2: Yes. The mother-baby tandem design improves melt stability and output quality, especially for viscous or heavily contaminated materials.

Q3: What is the pelletizing method used? How does it differ from die-face cutting?

A3: This system uses strand cutting with water cooling and air drying, which is more stable for materials that are difficult to pelletize via die-face systems.

Q4: Are dual degassing, dual filtration, and quick screen changes available?

A4: Dual venting and filtration are available as optional upgrades. A hydraulic quick screen changer is included as standard.

Q5: Does the system support automated operation and safety functions?

A5: Yes. It features one-touch operation, recipe storage, safety interlocks, and alerts for metal contamination.

Q6: What automation modules can be added? Are there limitations?

A6: Available options include metal detectors, vacuum pumps, odor removal units, and storage systems. A pellet cooling module is not currently supported.

Q7: Can the system layout be customized to fit our plant?

A7: The machine supports L-shaped line configurations but is not compatible with U-shaped layouts.