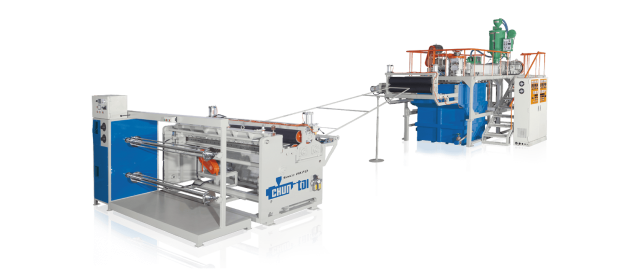

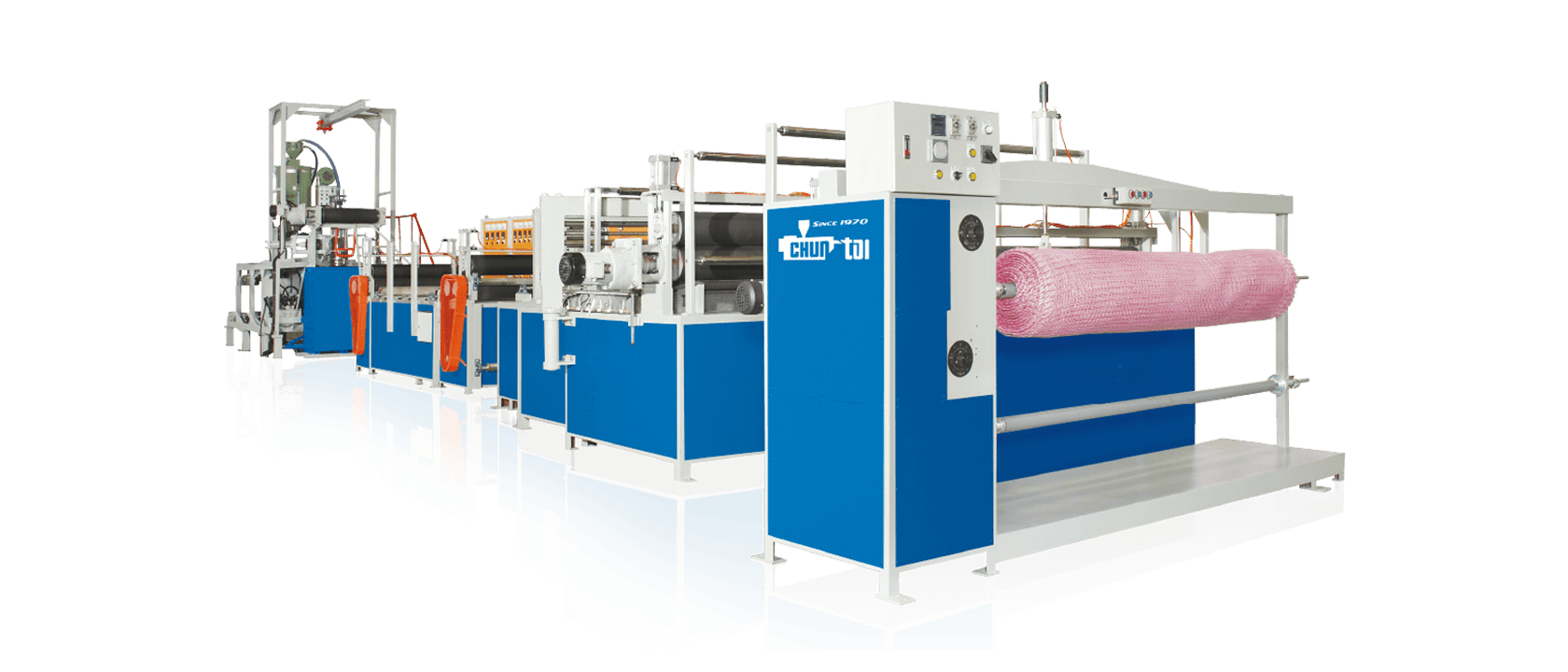

Square Shape Net Making Machine

Product Overview

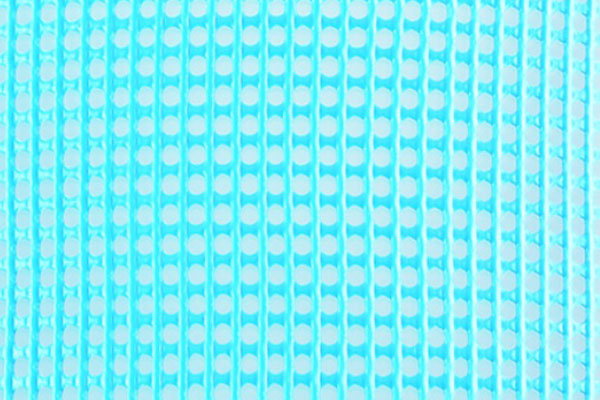

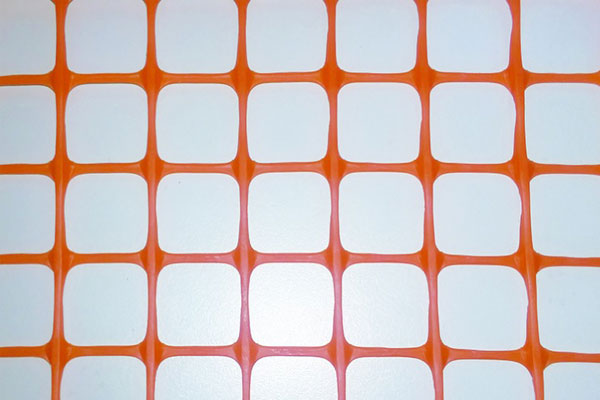

The Square Shape Net Making Machine is engineered for producing high-quality plastic square shape net used in agriculture, livestock enclosures, erosion control, aquaculture, and more. With a wide range of supported mesh sizes and net widths, the machine features quick-change mold systems for fast and flexible product switching.

Nets can be directly wound or routed for additional processing based on application needs. Its robust design, material compatibility, and customization options make it a versatile solution for large-scale mesh production.

Key Features

- Net Width up to 2 Meters:

Ideal for large-area applications such as fencing, slope protection, and containment barriers. - Wide Mesh Size Range (5–50 mm):

Supports a broad variety of structural and functional netting needs. - Compatible with PP and HDPE Materials:

Offers high weather resistance and processing stability. - Quick-Change Mold System:

Enables fast mesh design changes for different product specifications. - Multi-Color and Material Customization:

Supports compound blending and branded color schemes. - Flexible Post-Processing Options:

Finished nets can be wound, trimmed, or further fabricated as required.

Applications

- Agricultural nets (crop protection, plant support)

- Livestock fencing and animal enclosures

- Aquaculture netting and fish farming barriers

- Erosion control and slope stabilization meshes

Technical Specifications

| Item | Specification |

|---|---|

| Max Net Width | Up to 2 meters |

| Mesh Size Range | 5 mm – 50 mm |

| Supported Materials | PP and HDPE plastic pellets |

| Mold System | Interchangeable molds for various mesh patterns |

| Product Handling | Direct winding, trimming, or downstream processing |

| Color Options | Multi-color support with custom material blending available |

FAQ

- Q1: Can this machine produce different mesh sizes and patterns?

A1: Yes. Mesh size and pattern can be easily changed using interchangeable molds. - Q2: What materials are supported, and is pre-drying necessary?

A2: The machine supports PP and HDPE. Drying may be required depending on raw material moisture. - Q3: Is the finished net ready for use, or does it require additional processing?

A3: It can be used directly or further processed (e.g., edge trimming or cutting) as needed. - Q4: Can the machine produce multi-color nets?

A4: Yes. It supports multi-color production using custom-compounded materials.

Application :

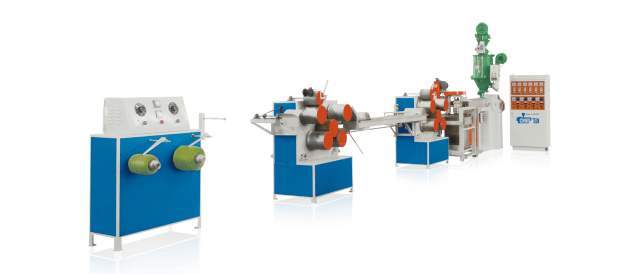

Related Products