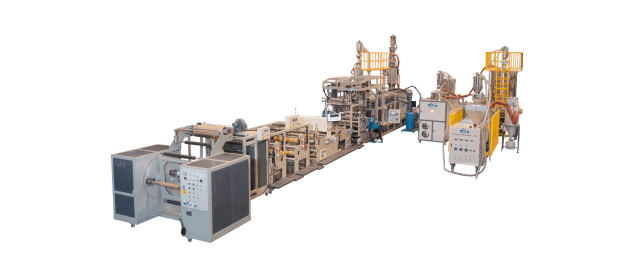

PP Sheet Extruder

Is the CHUN TAI PP Sheet Extrusion Line suitable for your production needs?

Common Production Challenges

- Inconsistent sheet thickness

- Unstable production affecting delivery schedules

- Heavy reliance on operator experience

How CHUN TAI Helps

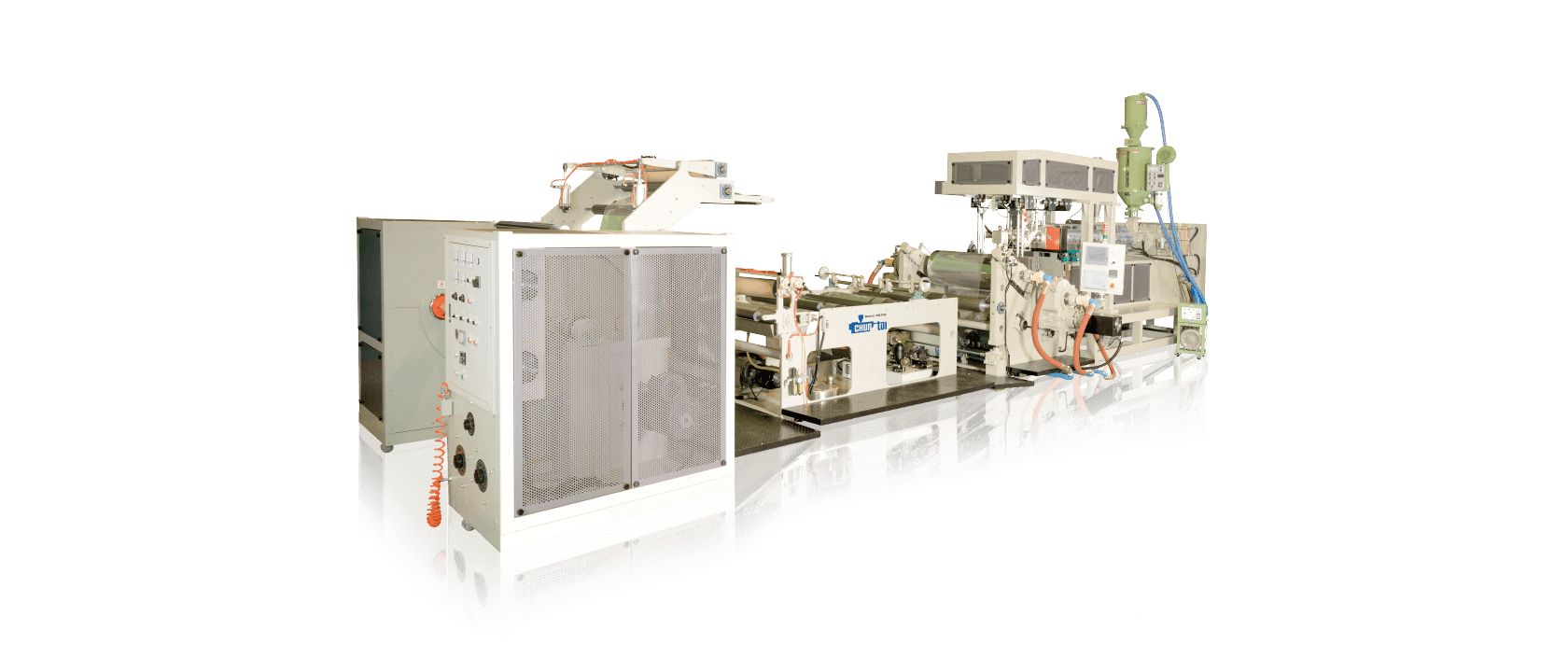

- Stable temperature control and extrusion design

- Durable structure to reduce downtime

- Clear operation logic for easier management

Design Concept & Positioning

The CHUN TAI PP Sheet Extrusion Line is designed for stable, high-volume production of PP sheets for food packaging and industrial use. In real production environments, sheet quality is often affected not by machine specifications, but by line stability, consistency, and operator dependency. Our focus is to keep PP sheet production running smoothly in daily operation, with fewer issues and easier management.

Key Design Features

-

Designed for stable continuous production:

Built with continuous production in mind, the extrusion structure and temperature control help maintain consistent sheet thickness and quality during operation, reducing rework and frequent adjustments.

-

Less reliance on operator experience:

Clear operation flow and intuitive settings allow operators with different experience levels to achieve stable output, making it suitable for shift-based production, overseas plants, and line replication.

-

Flexible configuration for different products and lines:

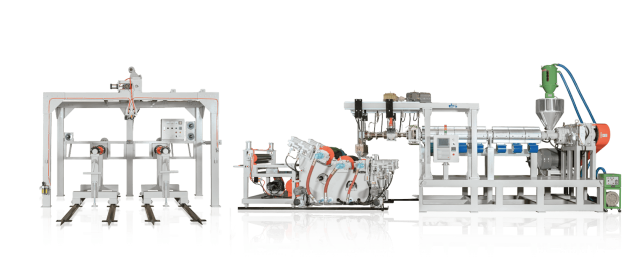

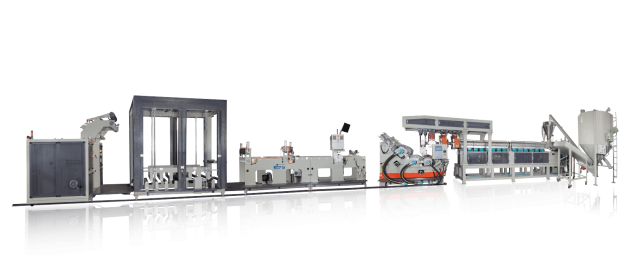

The system can be configured based on sheet thickness, width, layer structure, and material conditions, helping manufacturers build a PP sheet production line that fits existing factory layouts and capacity plans.

Industries & Applications

-

Production of disposable food containers, trays, lids, and dividers.

-

Manufacturing spoons, plates, and other single-use items for microwave or takeaway use.

-

PP cups, lids, and holders for high-volume food service brands.

-

Impact-resistant or rigid sheets for logistics liners and protective applications.

-

Supports the use of recycled PP materials to improve material reuse and circular production.

Specifications

| Item | Specification |

|---|---|

| Application Type | Produces solid sheets and multi-layer co-extruded sheets (up to 5 layers) |

| Extrusion Technology | ingle screw system; supports main/sub extruders for ABA, ABC structures |

| Applicable Materials | Compatible with various PP types, including virgin and recycled materials |

| Sheet Thickness Range | 0.3~1.8 mm |

| Sheet Width Range | Customizable based on client specifications |

| Output Capacity | Approx. 200–800 kg/hr |

| Control System | PLC with HMI interface and automatic temperature control |

| Layer Configuration | Supports ABA, ABC, AB, and up to 5-layer co-extrusion |

| Power Requirement | Configured based on plant voltage (V, Hz, kW) |

| Machine Dimensions | Approx. 20m × 6m × 3m |

| Customization Options | Thickness, width, and layer structure customizable; supports up to 5 layers |

FAQ

No. The system can be configured based on required capacity and is suitable for new production lines, capacity expansion, or equipment replacement.

Yes. It supports single-layer sheets and multi-layer co-extrusion structures such as ABA and ABC, with up to five layers depending on product requirements.

Yes. The system can be adjusted for virgin and recycled PP materials based on material behavior and production stability requirements.

Not necessarily. The system can be planned based on existing production conditions and upgraded later if needed.

Yes. Sheet thickness, width, and structure can be adjusted to support different product specifications on the same line.

Yes. Layout, power requirements, and capacity can be adjusted based on factory conditions. Providing basic production information helps us evaluate the most suitable configuration.