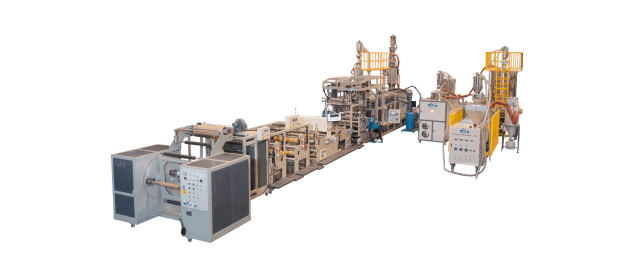

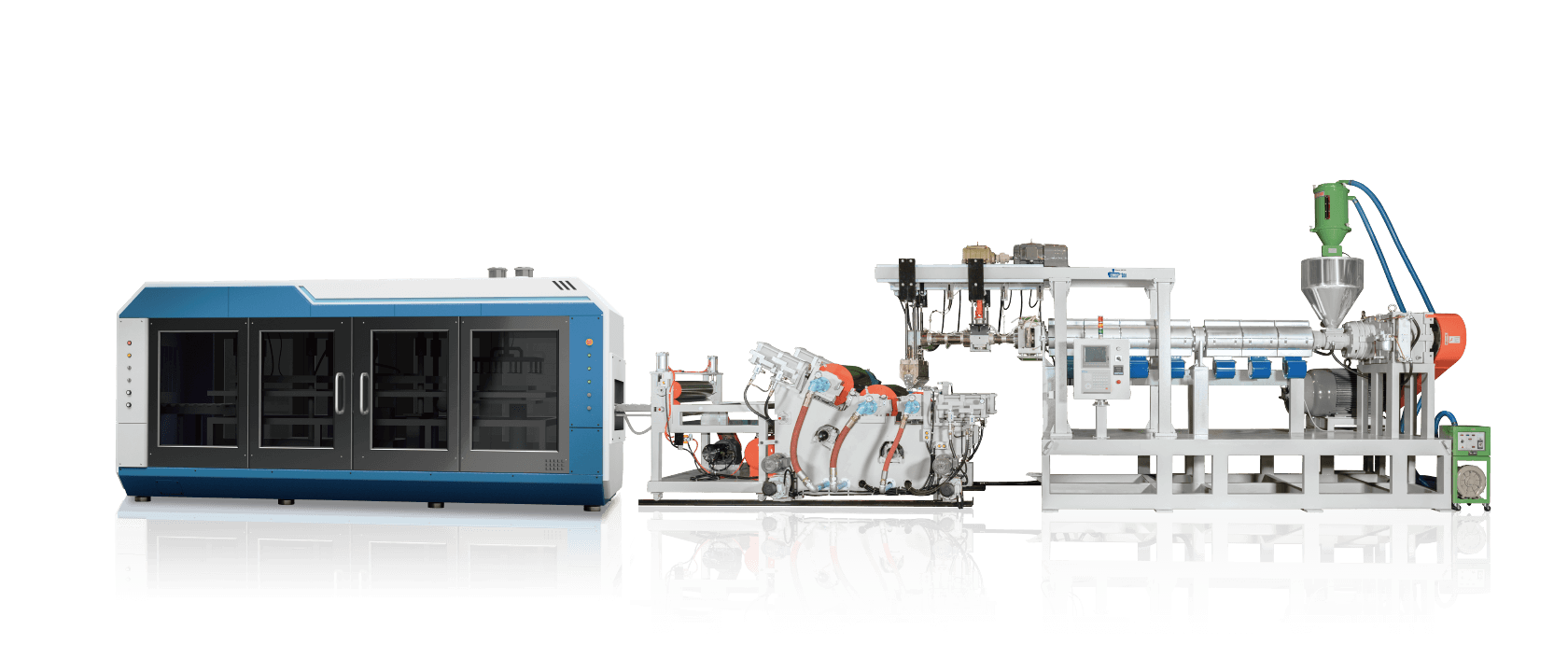

PP/PS Thermoforming Sheet Extruder

Is this PP / PS Thermoforming Sheet Extrusion Line suitable for your production needs?

If you are currently facing these issues

- Unstable sheet quality leading to fluctuating forming yield in inline production

- Sheets must be rewound and reheated, increasing energy use and floor space

- Sheet thickness or forming performance becomes inconsistent at higher output rates

How Chun Tai Helps Address Them

- Designed for thermoforming, ensuring stable sheet quality during production

- Direct inline connection eliminates rewinding and reheating

- Consistent forming performance maintained at high output speeds

Design Concept & Positioning

The PP(polypropylene) / PS(polystyrene) Thermoforming Sheet Extruder is developed for mass production in thermoforming applications, with a focus on maintaining consistent sheet quality under high-speed operation. The system can be directly connected to a thermoforming machine for inline production, eliminating sheet rewinding and reheating to reduce energy consumption, storage space, and overall process complexity. This design is suitable for thermoforming operations that require continuous production and consistent forming quality.

Key Design Features

-

High Throughput:

Designed for efficient production with adjustable output to meet different volume requirements.

-

Sheet Thickness Range:

Produces PP/PS sheets in thicknesses from 0.2 mm to 2.0 mm for a variety of forming needs.

-

Customizable Width:

Sheet width can be configured to match the specifications of downstream thermoforming machines, including wide-format applications.

-

Precision Control System:

Features a PLC-based system with accurate temperature regulation and thickness control to ensure consistent sheet quality.

-

Energy-Efficient Design:

Equipped with inverters and servo motors to reduce power consumption and support energy-saving production.

-

Modular Construction:

Built for easy maintenance and future upgrades, with flexible configurations to meet production requirements.

Industries & Applications

-

Used to produce cups, soup bowls, deli trays, and other disposable containers.

-

Suitable for sterile pharmaceutical cups, reagent containers, and sample trays.

-

Used for component trays, ESD-safe liners, and protective packaging.

-

Produces trays, display boxes, snack containers, and bulk packaging.

-

Manufactures microwaveable trays, dessert cups, and stackable food containers.

-

Supports the use of recycled PP and PS materials to promote material reuse and reduce environmental impact.

Specifications

| Item | Specification |

|---|---|

| Application Type | For producing thermoforming sheets (e.g., trays, cups); supports inline connection with thermoforming machines; no rewinding required |

| Extrusion Technology | Single screw extrusion; supports multi-layer co-extrusion |

| Compatible Materials | PP, PS only; consistent material properties required (no mixing) |

| Sheet Thickness Range | 0.3–1.8 mm |

| Sheet Width Range | Customizable based on thermoforming machine requirements |

| Output Capacity | Approx. 200–800 kg/hr (depending on thickness and conditions) |

| Control System | PLC with HMI; includes temperature automation and recipe storage |

| Cooling Configuration | Horizontal and vertical roller arrangement; includes inline thickness measurement |

| Inline Capability | Supports direct inline connection with thermoforming machines |

| Power Requirement | Configured according to plant voltage (V, Hz, kW) |

FAQ

Yes. It supports inline setup, removing the need for rewinding and allowing direct forming.

Yes. Multi-layer configurations can be set based on production needs.

No. It does not support PLA or other biodegradable materials.

It includes inline thickness measurement but does not have automatic thickness control.

Yes. Recycled materials can be used. Optional dehumidifying and blending systems are available.

No. The roller layout is fixed, with horizontal and vertical rollers included as standard.