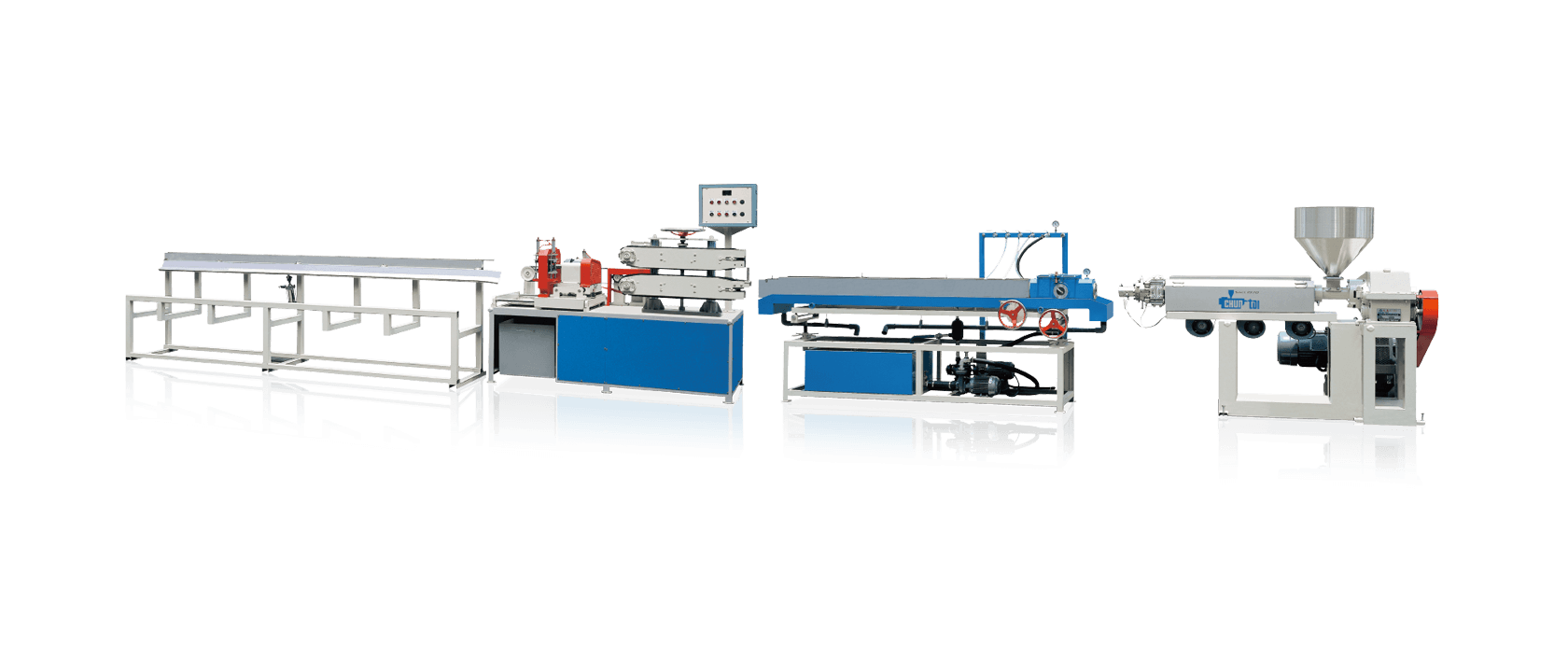

PVC-PP Rigid Pipe Making Machine

Product Overview

The PVC–PP Rigid Pipe Extrusion Line is engineered for the efficient production of durable plastic pipes made from either PVC or PP. With a flexible system configuration and customizable mold designs, this machine supports a wide range of pipe diameters and wall thicknesses, making it ideal for use in construction, infrastructure, and industrial fluid transport.

Pipes produced from this line are widely applied in water supply systems, electrical conduit installations, drainage networks, and chemical transfer lines. Designed for scalability and high processing stability, the system provides a robust solution for manufacturers seeking consistent output and long-term performance.

Key Features

- Versatile Pipe Dimensions: Supports customizable pipe diameters (Ø16 mm to Ø160 mm) and wall thicknesses for diverse application requirements.

- Quick-Change Mold System: Interchangeable molds and die heads simplify product changeover and improve production efficiency.

- Optional Co-Extrusion Capability: Multi-layer pipe production supported with independently controlled temperature zones for each layer.

- Material-Specific Screw Design: Optimized screw geometry tailored for PVC or PP ensures smooth extrusion and high-quality pipe output.

Applications

- Construction & Building: Water supply lines, fire-retardant casings, and electrical conduit pipes.

- Infrastructure: Underground ducts, drainage pipes, and agricultural irrigation systems.

- Industrial Processing: Chemical pipelines, suction and discharge lines.

- Home & Furniture: Decorative tubing, wiring covers, and pipe-based components.

Technical Specifications

| Item | Specification |

|---|---|

| Applicable Materials | PVC or PP pellets (not interchangeable in one line) |

| Pipe Diameter Range | Ø16 mm – Ø160 mm (customizable) |

| Wall Thickness Range | Adjustable per application |

| Output Capacity | Varies based on material and size (engineered per order) |

| Sizing & Cooling System | Vacuum calibration tank matched to pipe diameter |

| Mold & Tooling System | Standard molds included; fast-change system for easy replacement |

| Co-Extrusion Support | Optional; each layer with individual heating control |

| Material Line Switching | Not supported; PVC and PP require separate screw/barrel systems |

FAQ

- Can the machine produce custom pipe sizes?

Yes. Both pipe diameter and wall thickness can be tailored using custom-designed molds and die heads. - Can a single machine be used for both PVC and PP?

No. Due to different material characteristics, separate screw and temperature systems are required for each type. - Does the system support multi-layer co-extrusion?

Yes. Co-extrusion is available and allows for precise temperature control per layer, ensuring uniform quality. - Are mold changes quick and user-friendly?

Absolutely. The system includes fast-change tooling, and standard mold sets are provided with every machine order.

Application :

Related Products