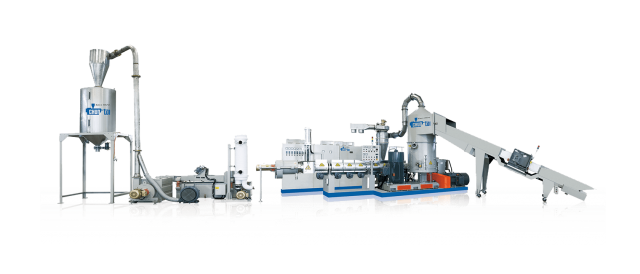

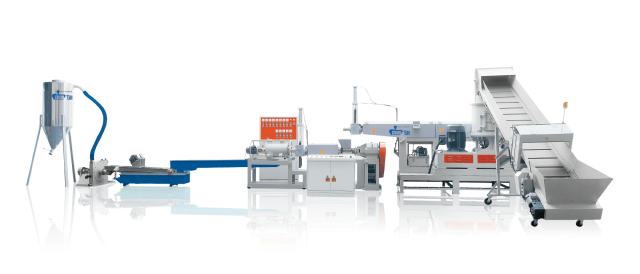

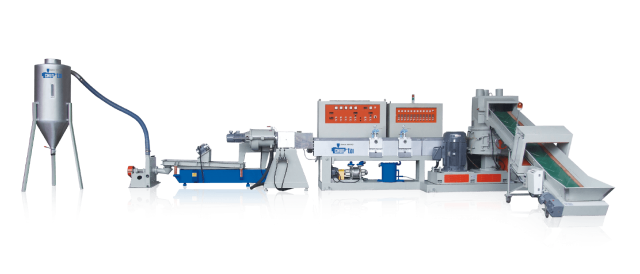

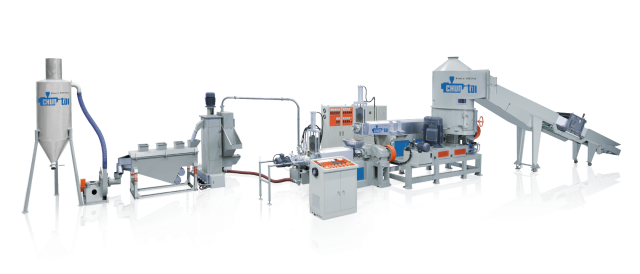

Squeezer

Product Overview

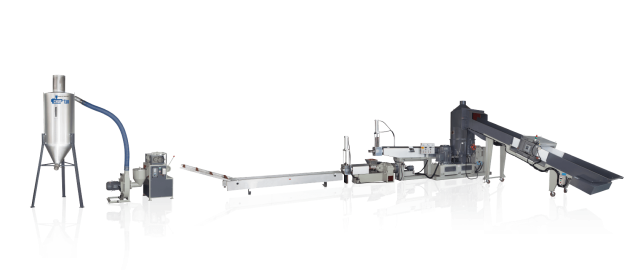

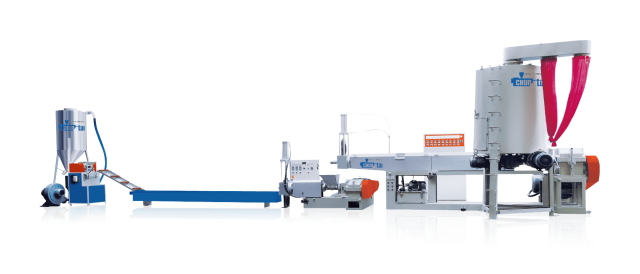

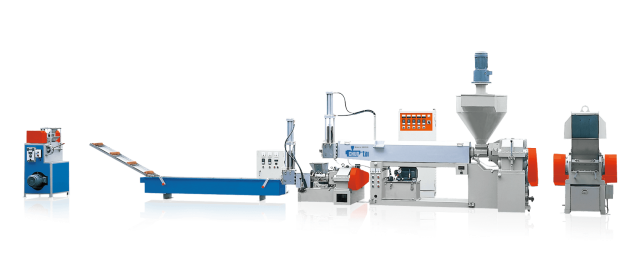

The Squeezer is specifically designed for post-washing plastic film recycling lines. It efficiently removes up to 95% of residual moisture from washed PE/PP films, reducing the final moisture content to below 5%. This enables direct feeding into an extruder without the need for additional drying, significantly lowering energy consumption in downstream processes. Thanks to its compact and streamlined design, the squeezer can operate either as a stand-alone unit or be seamlessly integrated into a complete washing and recycling system. It plays a vital role in enhancing both the efficiency and quality of film recycling operations.

Key Features

- High-Efficiency Moisture Removal: Removes up to 95% of moisture; final residual moisture remains below 5%.

- No Secondary Drying Required: Allows direct extrusion after dehydration, reducing energy use and system complexity.

- Tolerates Light Contamination: Capable of processing washed film containing minor impurities such as sand or dust.

- Flexible Installation: Supports both independent operation and full integration within washing lines.

- Standardized, Compact Design: Simplifies setup and ensures consistent performance across standard recycling configurations.

Applications

- Washed PE and PP film recycling

- Dehydration pretreatment to reduce energy load on extruders

- Modular upgrade for small to medium-sized washing or recycling systems

Technical Specifications

| Item | Specification |

|---|---|

| Processing Capacity | Approx. 300 kg/hr |

| Moisture Removal Efficiency | Up to 95%; final moisture < 5% |

| Applicable Materials | Washed PE/PP film; tolerates minor contamination (e.g., sand) |

| Operation Mode | Stand-alone or integrated into a full washing line |

| Downstream Integration | Direct feeding to extruders without additional drying |

| Model Type | Standardized fixed model for consistent installation and performance |

FAQ

- Q1: How much moisture can the squeezer remove?

A1: It removes approximately 95% of moisture, reducing final content to below 5%. - Q2: Can it process films with residual sand or impurities?

A2: Yes. It can handle washed films with light contamination, including small particles of sand or dust. - Q3: Is further drying required after using the squeezer?

A3: No. The material can be directly fed into an extruder without secondary drying. - Q4: Can it accommodate different film thicknesses or material types?

A4: The system is optimized for consistent, uniform film types and does not support parameter adjustments. - Q5: Can the machine be used independently?

A5: Yes. It can operate as a stand-alone unit but performs best when integrated into a complete washing line.

Related Products