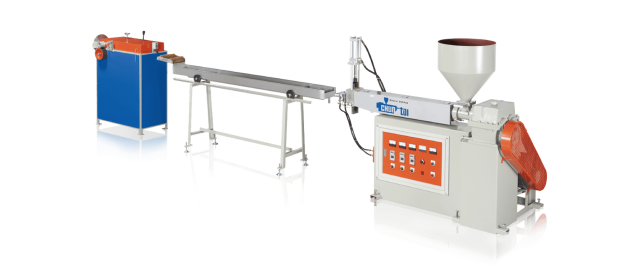

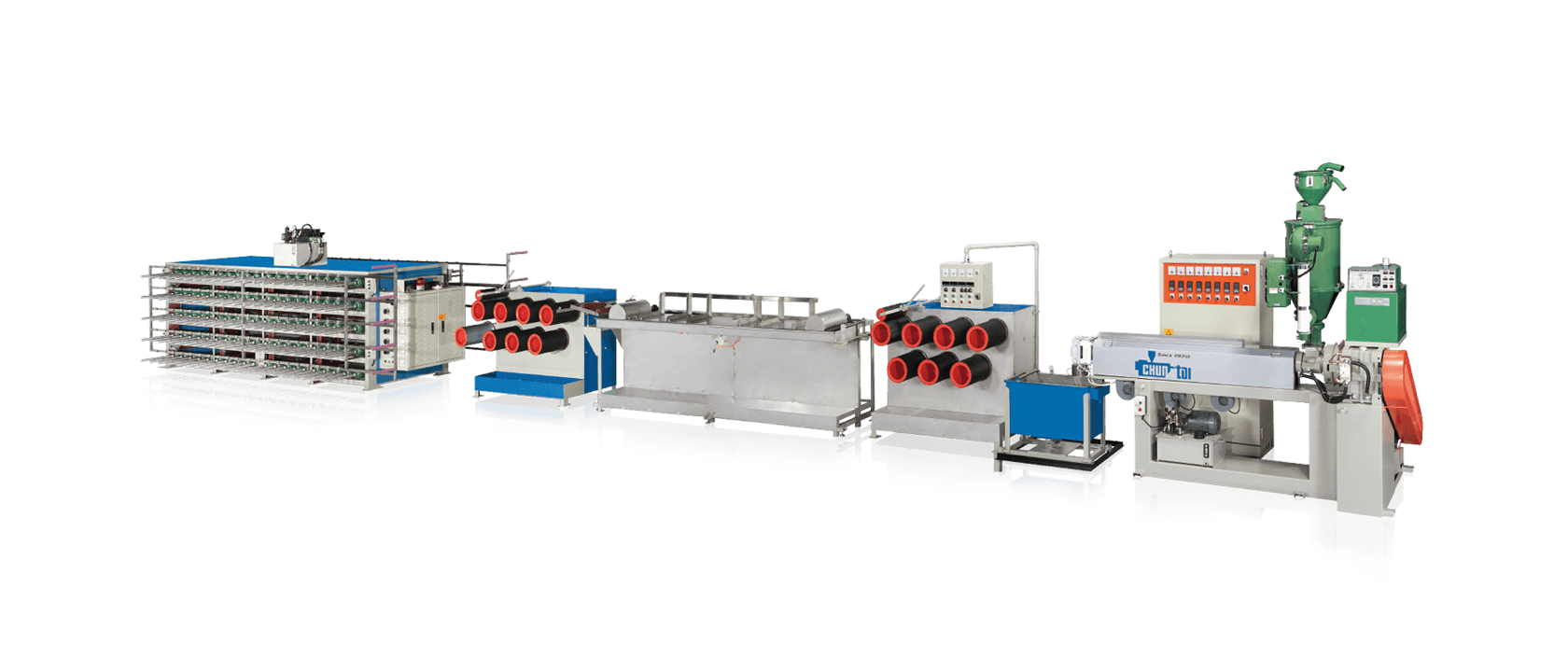

Plastic Monofilament Making Machine

Chun Tai Plastic Monofilament Making Machine suitable for your production needs?

Common Production Issues

- Inconsistent filament diameter affecting netting or rope quality

- Filament breakage or unstable winding at higher production speeds

- Long downtime when changing filament diameter specifications

How Chun Tai Helps

- Stable filament diameter control for consistent product quality

- Hot-water cooling combined with single-axis winding for stable high-speed operation

- Quick die head replacement to reduce changeover downtime

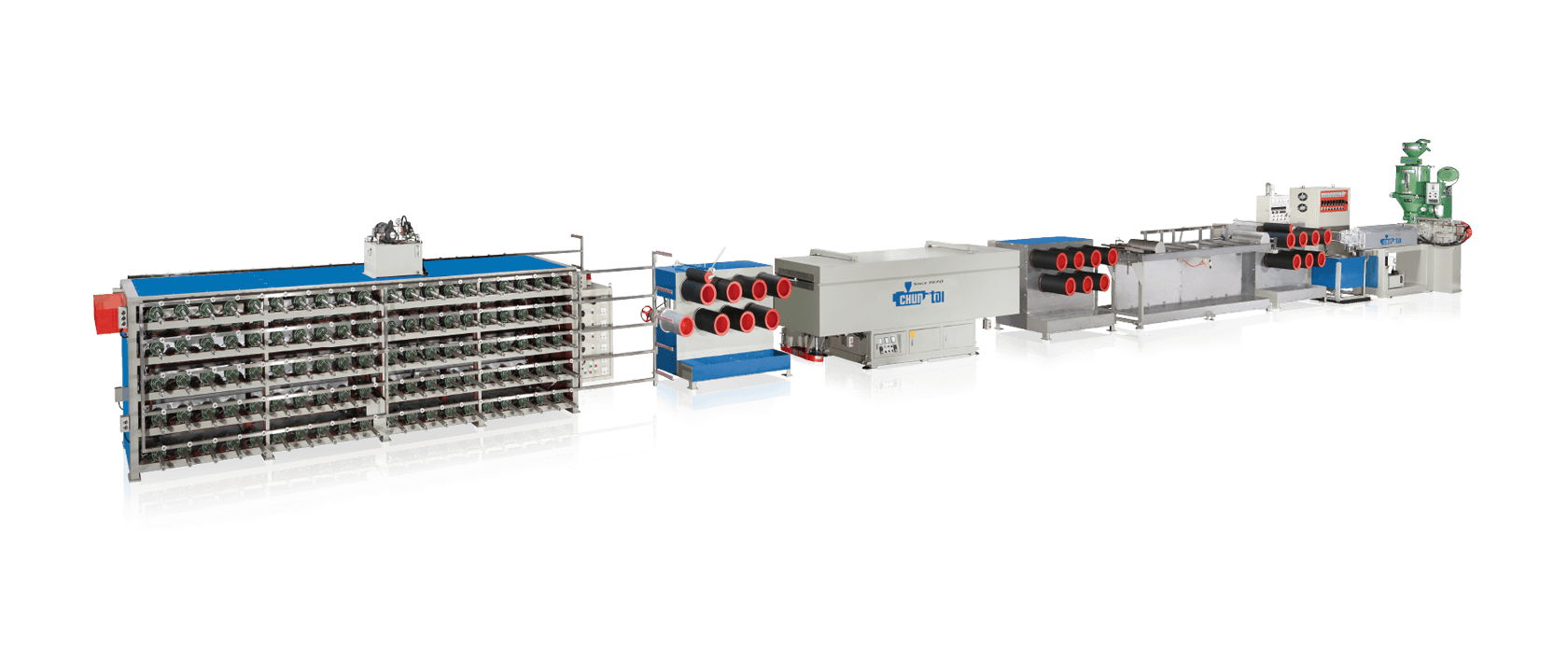

Design Concept & Positioning

This machine is developed specifically for plastic monofilament extrusion, with a focus on stable filament diameter control and practical production operation. By combining a hot-water cooling system with a high-speed single-axis winding unit, consistent filament shaping can be maintained across different diameter ranges during continuous operation. Quick die head replacement allows efficient product size changes, while compatibility with blends of virgin and recycled materials helps reduce material costs without compromising filament strength and quality. The system is positioned as a practical solution for manufacturers seeking reliable, flexible, and cost-controlled monofilament production.

Key Design Features

-

Flexible Filament Diameter:

Quickly swap die heads to produce different filament diameters for applications ranging from mesh and netting to utility rope.

-

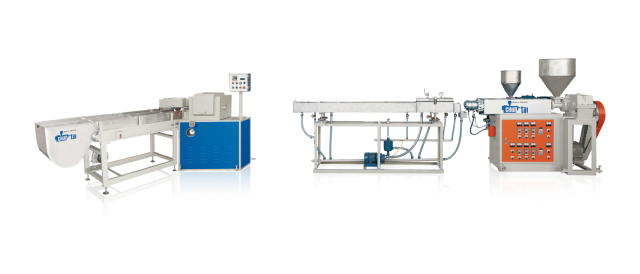

Hot Water Cooling System:

Ensures uniform cooling and precise filament shaping for stable, high-quality output.

-

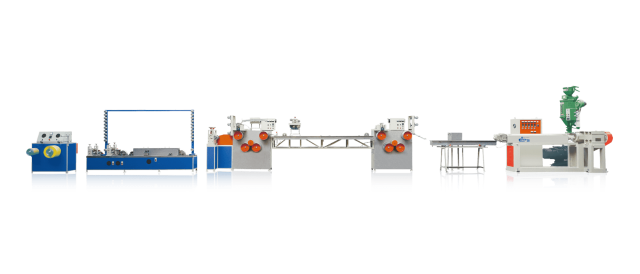

High-Speed Production:

Achieve line speeds of up to 80 meters per minute, supporting continuous, high-volume manufacturing.

-

Tool-Free Die Head Replacement:

Minimize downtime with quick-change tooling for faster transitions between product sizes.

-

Supports Recycled Materials:

Compatible with blends of recycled and virgin thermoplastics, offering a sustainable, cost-effective solution without sacrificing performance.

Industries & Applications

-

Filaments for fishing lines and nets

-

Screen mesh, shade nets, window coverings

-

Ropes, strapping, twine

-

Plant tie lines, greenhouse string, crop support cords

Specifications

| Item | Description |

|---|---|

| Filament Diameter | Adjustable via die head (customizable per order) |

| Max Line Speed | Up to 80 m/min |

| Cooling System | Hot-water cooling tank with recirculation |

| Winding | Single-axis manual take-up |

| Material Support | Compatible with multiple thermoplastics; allows recycled blends |

| Cutting & Automation | Manual operation; automatic cutting not supported |

| Stretch Control | Diameter linked to drawing speed (no closed-loop feedback) |

| Heat Setting | Enabled for post-drawing thermal shaping and take-up stability |

FAQ

Yes. It supports a wide range of thermoplastics. Die change is only needed when switching to a different filament diameter.

Slightly. Blending with recycled material may reduce tensile strength, so maintaining an optimal mix ratio is recommended.

No. Cutting and winding are handled manually in this configuration.

Fine-tune drawing speed and heat settings to control filament size consistently.