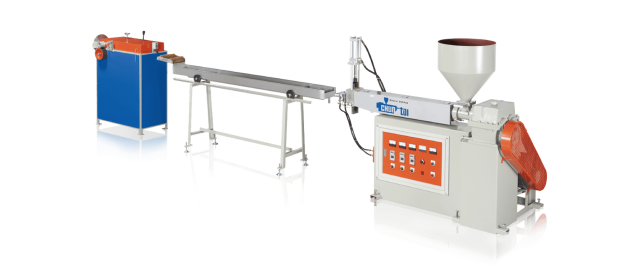

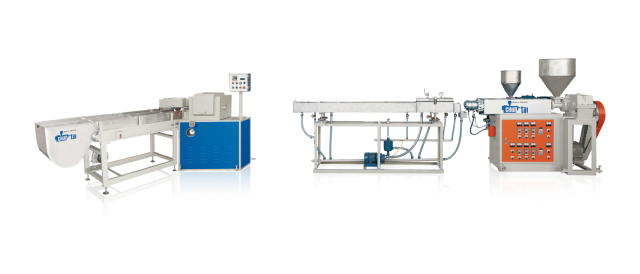

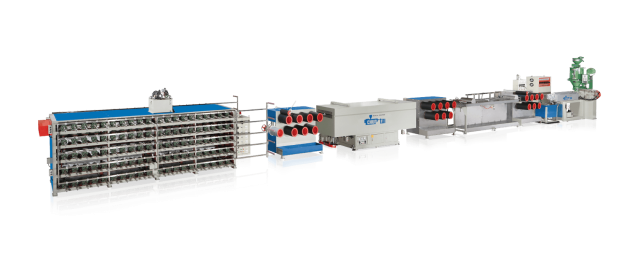

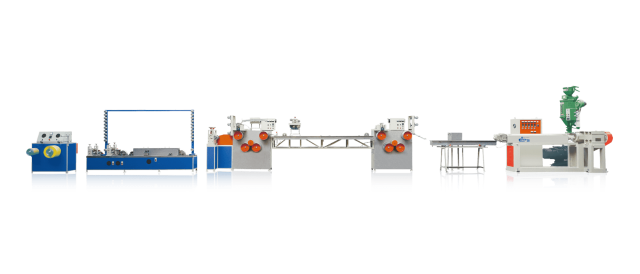

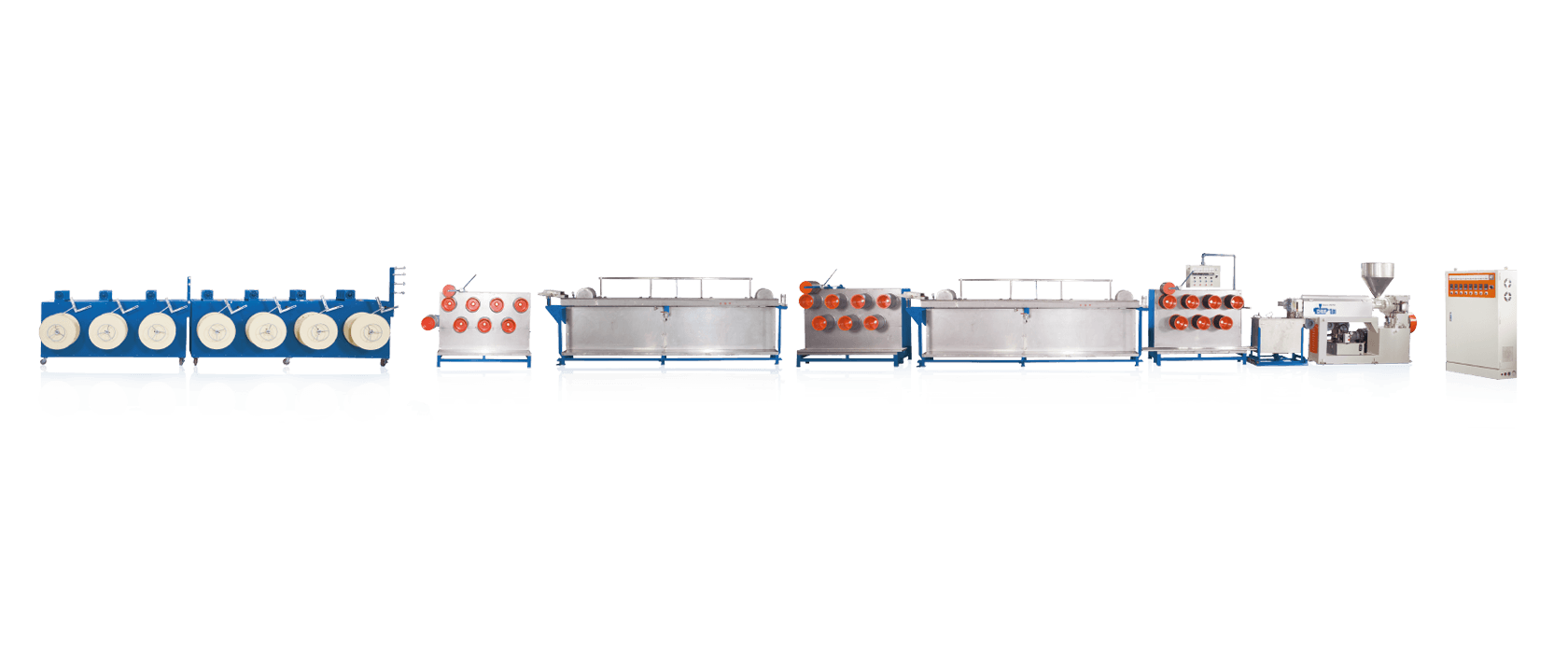

PP False Vine Making Machine

Flexible System for Single-Color, Dual-Color, Solid, and Hollow Wicker Profiles

Product Overview

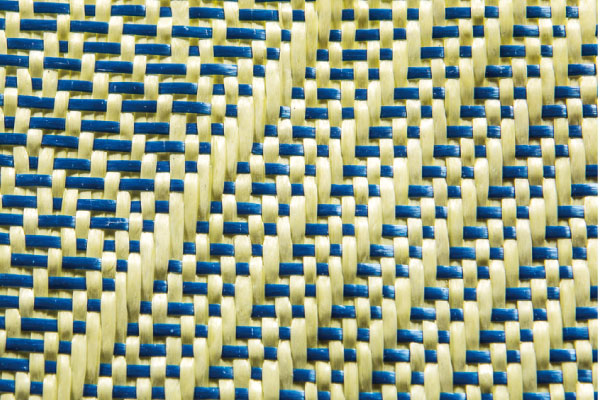

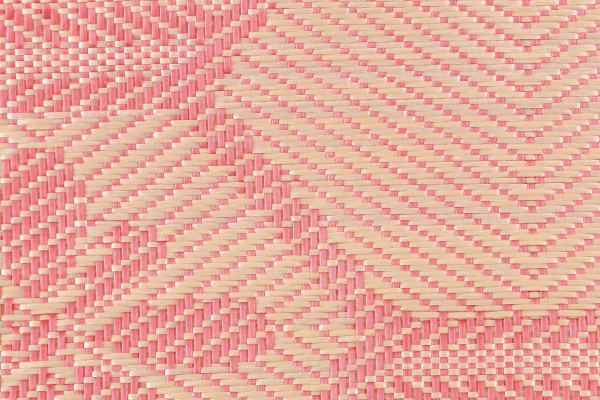

This extrusion system is engineered for the efficient production of synthetic wicker strips used in outdoor furniture, woven mats, sunshades, and decorative applications. Capable of handling single-color, dual-color, solid-core, and hollow-core profiles, the machine offers excellent flexibility through modular molds and optional co-extrusion. It also supports a blend of virgin and recycled PP, delivering sustainable production without compromising visual or structural quality.

Key Features

- Versatile Output Capabilities:

Supports production of solid and hollow strips in both single- and dual-color formats to meet diverse design needs. - Dual-Color Co-Extrusion:

Optional auxiliary extruder enables crisp two-tone finishes with excellent material separation. - Quick-Change Heated Mold System:

Integrated die heating simplifies size or pattern changes, reducing downtime and improving throughput. - Recycled PP Compatibility:

Enables controlled use of recycled polypropylene, ensuring stable quality and reduced raw material costs.

Application Areas

- Outdoor Furniture – Rattan-style chairs, sofas, and tables

- Woven Home Goods – Decorative mats, baskets, headwear

- Architectural Decor – Privacy screens, woven panels, shade curtains

Technical Specifications

| Item | Description |

|---|---|

| Strip Dimensions | Customizable (width & thickness based on client specs) |

| Production Rate | 50–80 kg/hour |

| Mold System | Heated quick-change system |

| Supported Configurations | Single/dual-color; solid/hollow profiles |

| Co-Extrusion | Requires auxiliary extruder for two-tone production |

| Recycled Material Support | Yes, with proper blending for consistent appearance and strength |

Frequently Asked Questions (FAQ)

- Q1: How fast is the mold change process?

A1: The machine features a heated mold system, allowing quick and tool-free switching with minimal downtime. - Q2: Will recycled PP affect product quality?

A2: Not if blended properly. The system is designed to handle a proportion of recycled PP without compromising aesthetics or durability. - Q3: What’s required for dual-color production?

A3: A secondary (co-) extruder is necessary to feed two materials simultaneously into the mold.