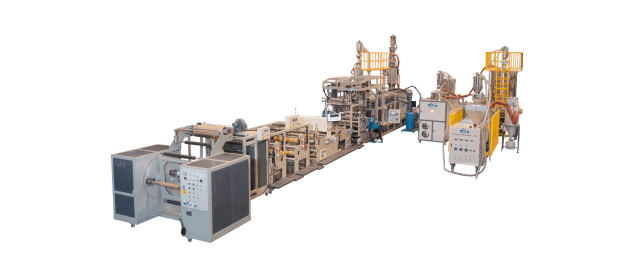

PP/HIPS Sheet Extruder

Is the Chun Tai PP / HIPS Sheet Extrusion Line suitable for your production needs?

Common Production Issues

- Inconsistent PP/HIPS sheet thickness affecting thermoforming yield

- Unstable conditions when material formulations or recycled content ratios change

- Quality variation between shifts or operators

How Chun Tai Addresses Them

- Extrusion and temperature control designed for stable sheet thickness

- Configurable setup for different PP/HIPS material conditions

- Clear operation logic to reduce operator-related variation

Design Concept & Positioning

The Chun Tai PP / HIPS Sheet Extrusion Line is designed for mass production of polypropylene (PP) and high-impact polystyrene (HIPS) sheets used in thermoforming applications such as food, medical, and electronic packaging.

The design focuses on maintaining consistent output under different production volumes and material conditions, with emphasis on process stability, controllable operation, and practical flexibility to match real production requirements.

Key Design Features

-

High Throughput:

Built for efficient output to accommodate both small and large-scale production needs.

-

Adjustable Sheet Thickness:

Capable of producing PP and HIPS sheets in thicknesses ranging from 0.2 mm to 2.0 mm for a wide range of applications.

-

Customizable Extrusion Width:

Supports sheet widths up to 1200 mm, with die widths configurable to meet specific production requirements.

-

Precision Control System:

Integrated PLC system with precise temperature regulation and adjustable thickness control for consistent product quality.

-

Energy Efficiency:

Equipped with inverters and servo motors to reduce energy consumption and support sustainable operation.

-

Modular and Adaptable Design:

Easy to maintain and upgrade, with flexible configurations to meet evolving production demands.

Industries & Applications

-

Used to produce thermoformed beverage cups, cold food trays, and ready-to-eat meal containers.

-

Suitable for trays and sterile packaging for diagnostic equipment and medical supplies.

-

Ideal for component trays, anti-static inserts, and structural carriers.

-

Used to produce storage boxes, compartment trays, and durable dust covers.

Specifications

| Item | Specification |

|---|---|

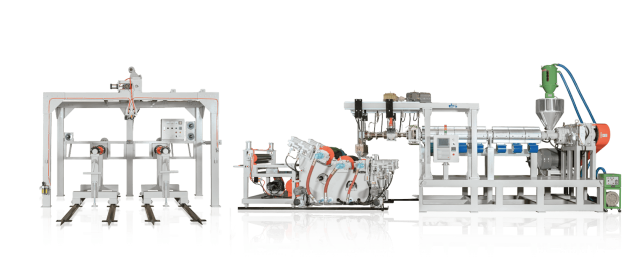

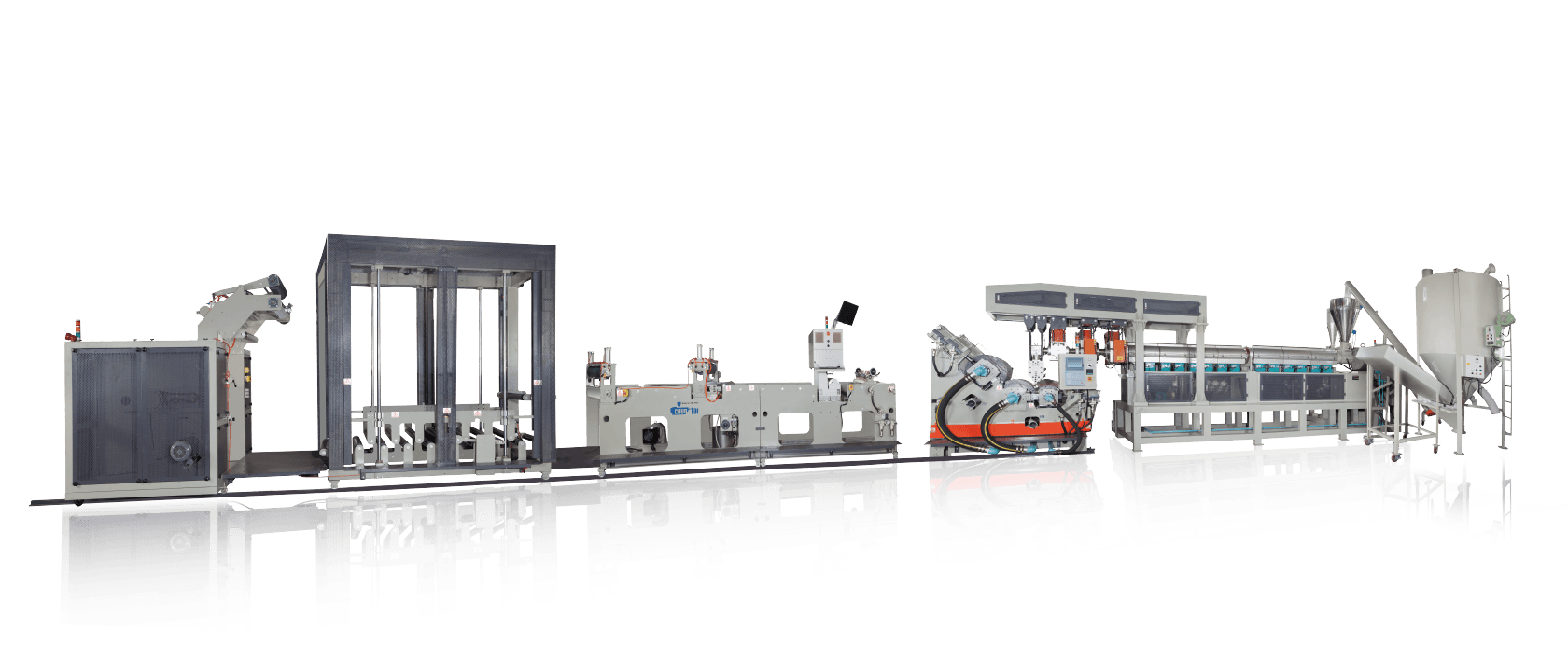

| Application Type | For PP and HIPS thermoforming sheet production; supports two- and three-layer co-extrusion |

| Extrusion Technology | Single screw extrusion; supports ABA, ABC configurations with main and sub extruders |

| Compatible Materials | PP, HIPS; compatible with both recycled and mixed materials |

| Sheet Thickness Range | 0.3–1.8 mm; adjustable based on customer requirements |

| Sheet Width Range | Customizable die width according to production needs |

| Layer Configuration | Two- and three-layer co-extrusion supported; individual layer thickness adjustable |

| Output Capacity | Approx. 200–800 kg/hr |

| Control System | PLC with HMI; includes automated temperature control and recipe memory |

| Thickness Control | Inline thickness measurement included; optional automatic thickness control available |

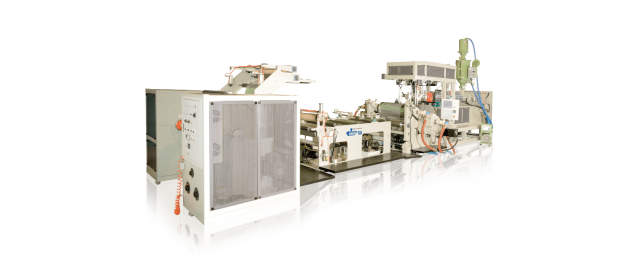

| Cooling System | Calender rolls in standard “J-type” or horizontal configuration; upgradeable |

| Inline Forming | Supports direct inline connection with thermoforming machines; rewinding not required |

| Power Requirement | Configured based on plant voltage (V, Hz, kW), tailored to customer specifications |

FAQ

Yes. It supports ABA, ABC, and other multi-layer configurations, with independently adjustable layer thickness.

Yes. The system supports the use of recycled and edge-trimmed materials.

Yes. The PLC + HMI interface includes recipe storage for convenient operation.

Inline thickness measurement is included; automatic thickness control is available as an option.

Not included by default. Some modules are available as optional upgrades.

Yes. Inline forming is supported, eliminating the need for sheet rewinding and saving space.

Both sheet width and thickness can be customized according to production requirements.