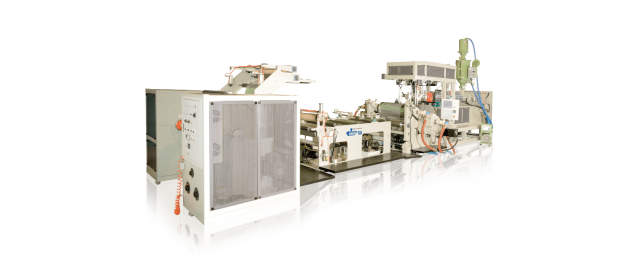

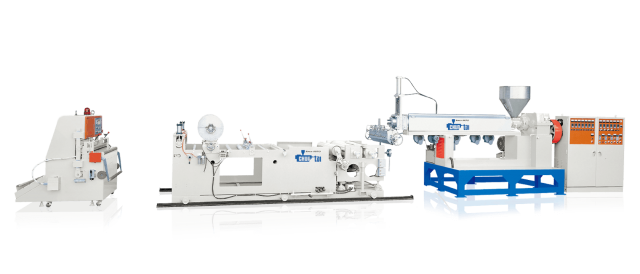

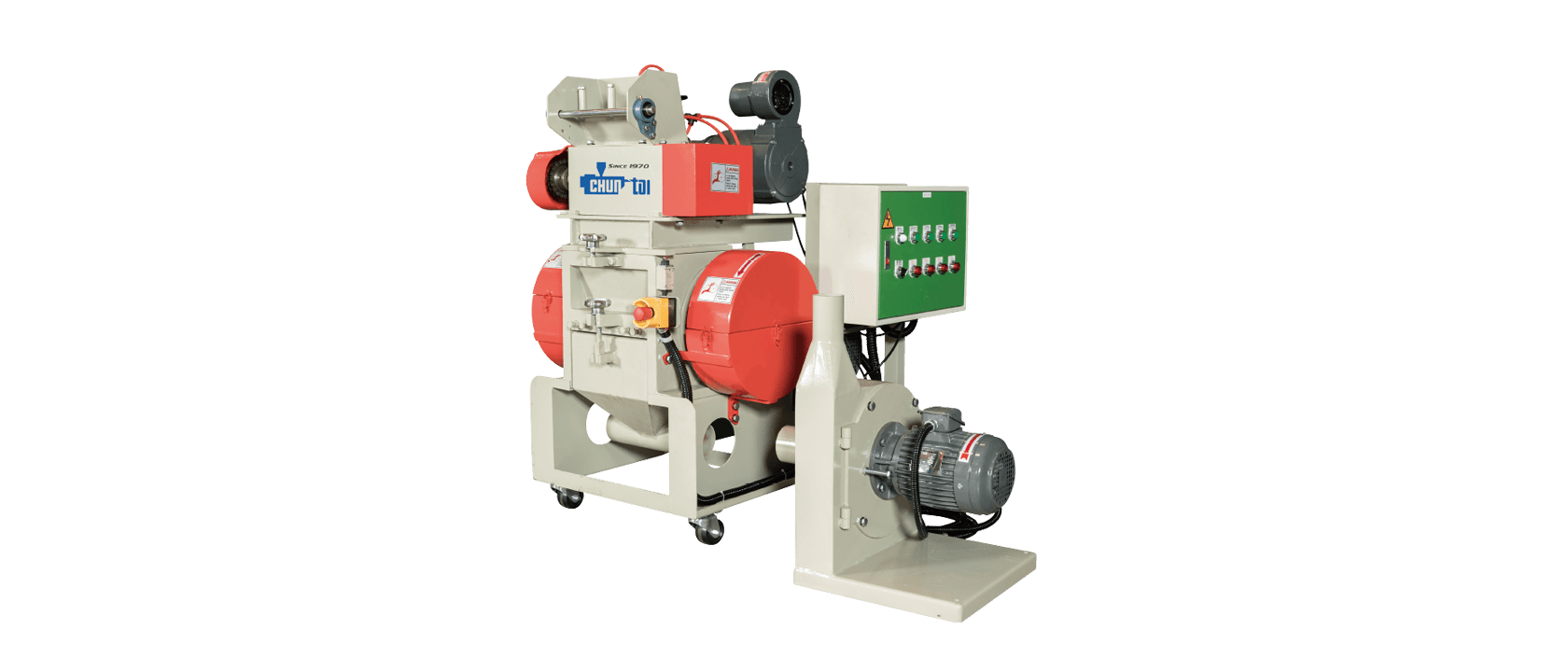

Online Side Trim Recycling

Product Overview

The Online Side Trim Recycling Machine is designed for the in-line recovery of plastic film edge trims during processes such as blown film, cast film, bubble film, and sheet extrusion. It efficiently recycles a wide range of plastic film materials, including PE, PP, PET, CPP, BOPP, APET, PET-G, PS, PVC, and ABS. Trimmed materials are immediately fed back into the main extruder for reprocessing, helping to reduce raw material waste and improve cost efficiency.

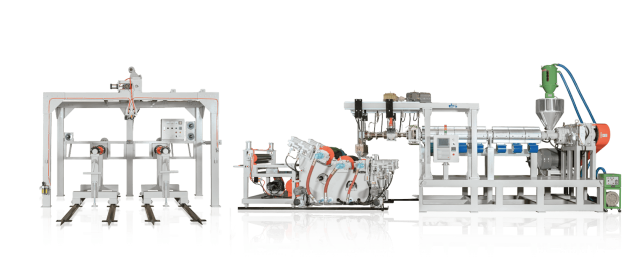

Key Features

- In-Line Edge Trim Recycling:

Recycles trims directly from the production line to increase material usage and reduce waste. - Labor and Time Efficiency:

Reduces manual handling to streamline operations and improve workflow. - Energy Saving:

Lowers energy consumption by approximately 10–20%, while also reducing operator costs. - Easy Integration:

Requires no special layout and can be seamlessly installed into existing production lines. - Closed-Loop Compatibility:

Supports closed-loop recycling by directly feeding trimmed material back into the extrusion process.

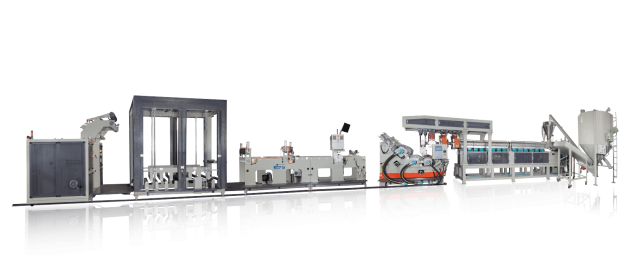

Applicable Industries

Ideal for film production lines across various industries, including:

- Food Packaging

- Stationery

- Home Appliances

- Construction

- Agriculture

- Fisheries

- Medical and Healthcare

- Electronics

- Automotive

- General Industrial Manufacturing

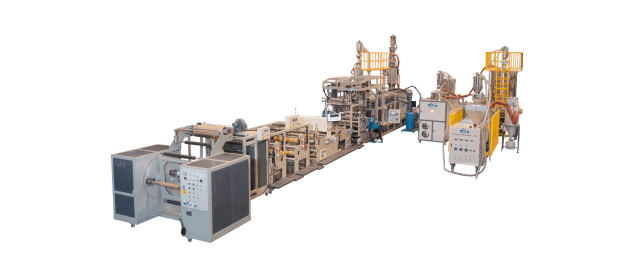

Technical Specifications

| Item | Specification |

|---|---|

| Applicable Film Thickness | Up to 2 mm |

| Processing Capacity | Approx. 30–50 kg/hr |

| Trim Conveyance Method | Pneumatic blower |

| Electrical Requirement | Configured to match customer’s plant voltage (V, Hz, kW) |

Frequently Asked Questions (FAQ)

- Q1: What types of plastic film materials can this machine process?

A: It supports PE, PP, PET, CPP, BOPP, APET, PET-G, PS, PVC, and ABS. - Q2: Can the machine be installed on existing production lines without modification?

A: Yes, it can be integrated into existing lines without requiring layout changes. - Q3: Does this machine use a vacuum or compressed air system?

A: No. It uses a blower-based conveying system and does not include vacuum or compressed air feeding.