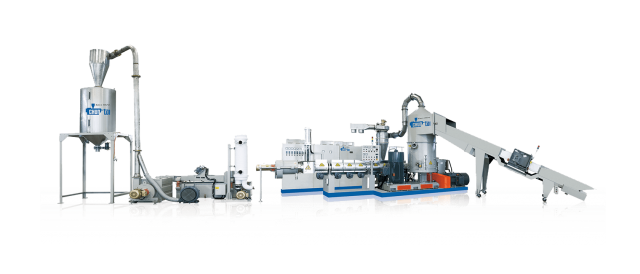

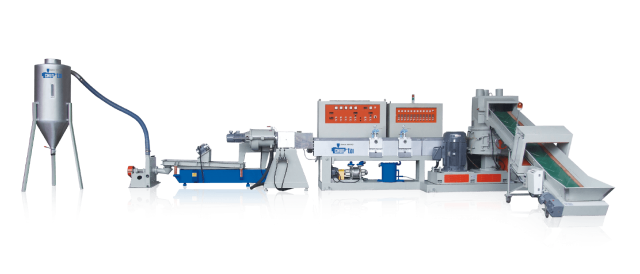

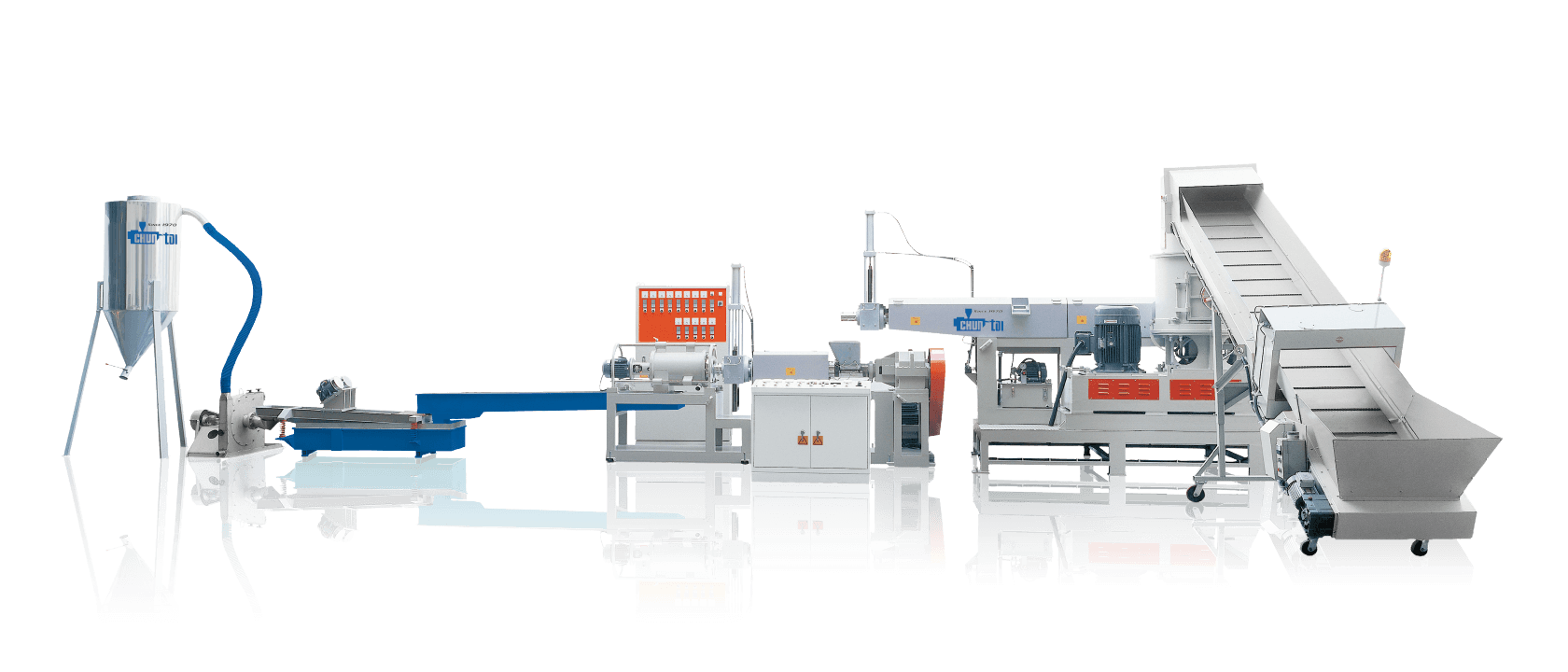

Die-face Cutting Pelletizer

Product Overview

The die-face cutting system is engineered to replace traditional strand cutting and water tank cooling, offering an efficient solution for recycling materials with high levels of contamination or moisture—such as agricultural film, printed film, packaging trim, and washed plastic sheets. This all-in-one 3-in-1 system integrates shredding, extrusion, and die-face pelletizing in a compact unit. Equipped with a tandem (mother-baby) extrusion configuration and dual-stage filtration, the system ensures high pellet purity and consistent processing. It supports downstream processes including film blowing, injection molding, and profile extrusion. With a small footprint, simplified workflow, and stable performance, the machine is particularly suitable for mid- to large-scale recycling plants, especially when handling heat-sensitive materials like LDPE, HDPE, LLDPE, and PP.

Key Features

- 3-in-1 Integrated System: Combines shredding, extrusion, and pelletizing in a single unit to reduce floor space, labor demand, and operational complexity.

- Tandem Extrusion Design: Dual extruders (main and sub) enhance material throughput and improve filtration efficiency for stable pellet output.

- Dual Degassing & Filtration Die Head: Effectively removes ink, moisture, and residual impurities from washed or contaminated input materials.

- Automated Die-Face Cutting System: Designed for soft film materials, this cutting system improves pellet uniformity while eliminating the need for water cooling.

- Energy-Saving Inverter Control: Equipped with a variable frequency drive (VFD) to optimize energy consumption and reduce electricity costs.

- Flexible Modular Options: Supports optional modules including vacuum pumps, metal detectors, quick-change screens, and advanced cooling systems.

Application Scope

This system is designed to process and pelletize a variety of thermoplastic materials, including:

- Agricultural films and industrial packaging films

- Printed films and ink-contaminated flexible plastics

- Washed plastic sheets, post-industrial scrap, and trimmed waste

- Thermoplastics such as LDPE, HDPE, LLDPE, PP, and PS

Note: This model is not designed for inline integration with primary extrusion lines but can be connected downstream of washing systems.

Technical Specifications

| Item | Specification |

|---|---|

| Recyclable Materials | LDPE, HDPE, LLDPE, PP, PS (films and sheets) |

| Material Condition | Suitable for washed, high-moisture, and ink-contaminated materials |

| Extrusion Technology | Tandem (mother-baby) extruders with dual degassing and filtration |

| Pelletizing Method | Automated die-face cutting system |

| Cooling System | Air cooling with optional enhanced cooling modules |

| Energy Efficiency | Variable frequency drive (inverter control) |

| Optional Modules | Vacuum pump, metal detector, cooling unit, quick-change screens |

| Output Capacity | Approx. 200–1500 kg/hr (dependent on material type and condition) |

FAQ

- Q1: What types of plastic waste can this machine process?

A1: It is ideal for agricultural film, printed film, packaging trim, and washed plastic materials with high contamination levels. - Q2: Can it handle high-moisture or ink-heavy materials?

A2: Yes. The dual degassing and filtration systems are designed to handle high-moisture content and ink-laden inputs efficiently. - Q3: What are the end-use applications of the recycled pellets?

A3: The pellets can be used for film blowing, injection molding, profile extrusion, and various other plastic processing methods. - Q4: Is the machine compatible with other upstream or downstream systems?

A4: While it does not support inline integration with primary extrusion lines, it can be connected to downstream washing or drying systems. - Q5: What is the machine’s maximum output capacity?

A5: The throughput ranges from approximately 200 to 1500 kg/hr, depending on the input material and its condition. - Q6: Does the system offer energy-saving and upgrade capabilities?

A6: Yes. It features inverter control for energy efficiency and supports optional upgrades including metal detection, vacuum modules, and enhanced cooling systems.