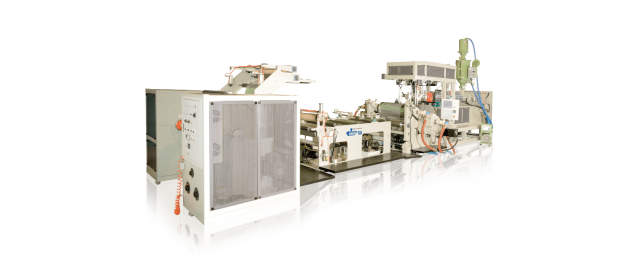

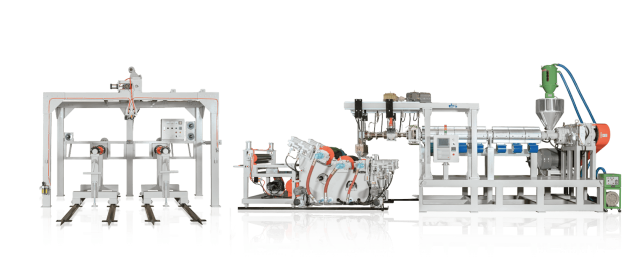

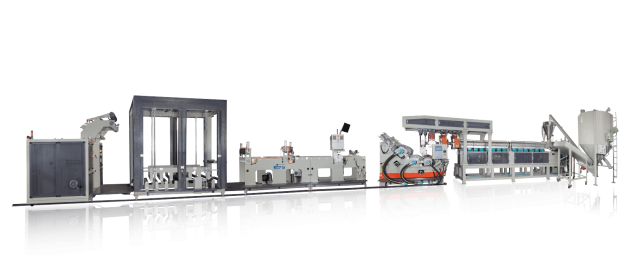

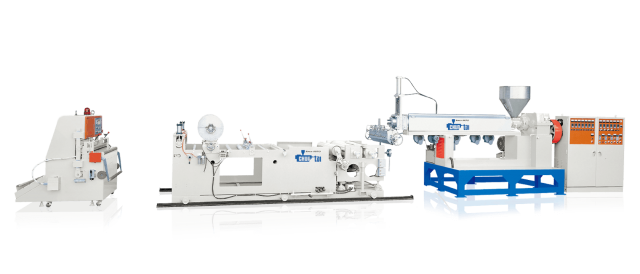

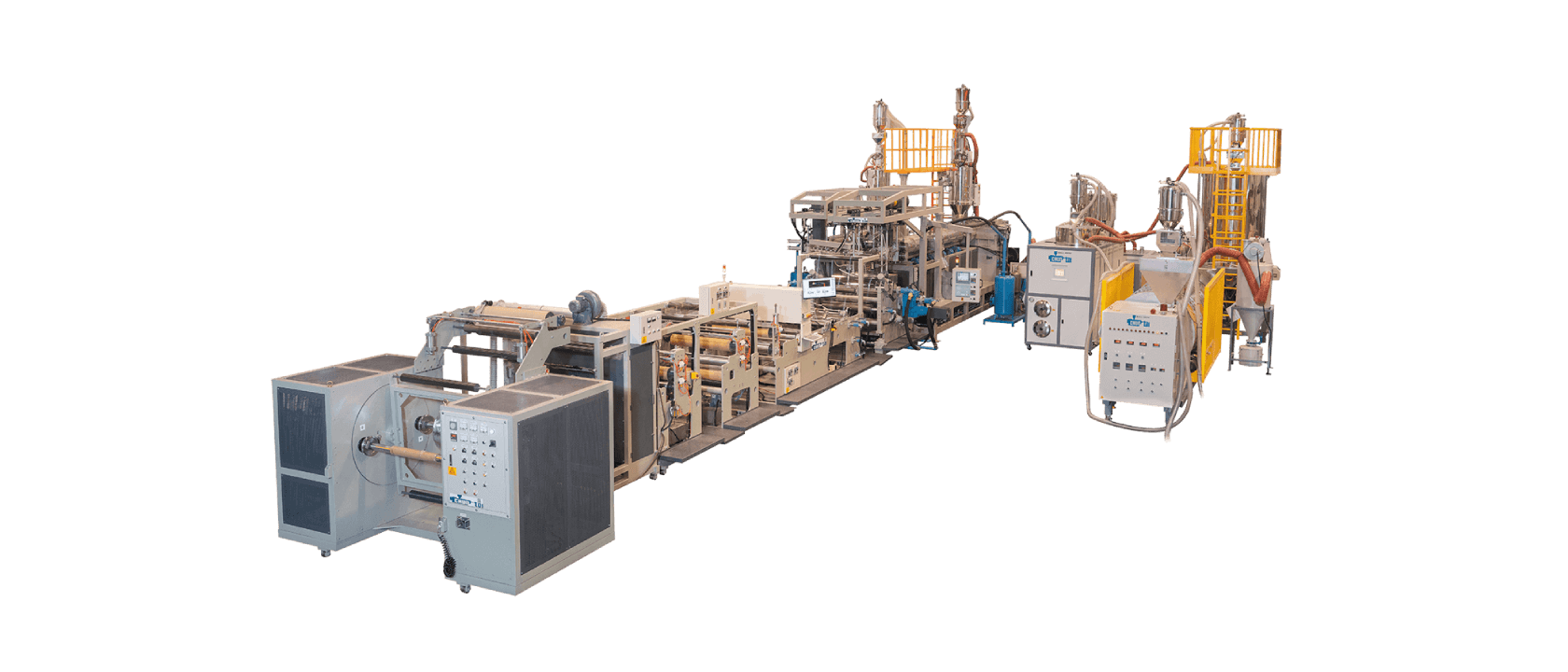

PET / PLA / Decomposable / Vacuum Forming Sheet Extruder

Is Chun Tai’s PET / PLA / Decomposable Vacuum Forming Sheet Extruder suitable for your production needs?

Common Production Challenges

- Eco-friendly materials are sensitive, making yield difficult to stabilize

- Long adjustment time when switching between different materials

- Small deviations in temperature or settings can affect forming results

How Chun Tai Helps

- Stable temperature control across forming-related sections

- Reduced impact of material property differences on production

- Clear setup logic to minimize repeated trial adjustments

Product Positioning & Design Concept

The Chun Tai PET / PLA / Compostable Vacuum Forming Sheet Extrusion Line is designed for food packaging and environmentally focused packaging applications. It is suitable for production environments that require both forming stability and flexibility in material handling. When processing PET, PLA, or compostable materials, forming quality depends more on temperature stability and ease of control than on individual specification numbers. This system is designed to keep material behavior predictable under production conditions, helping maintain stable operation and reducing daily management complexity.

Key Design Features

-

Designed for eco-friendly material forming behavior:

Temperature control and extrusion configuration are set based on the forming characteristics of PET, PLA, and compostable materials, helping maintain sheet thickness and forming quality while reducing defect rates.

-

Suitable for stable production and management:

Clear operating logic reduces reliance on individual operator experience, making it suitable for long-term production and multi-shift factory environments.

-

Configurable based on vacuum forming requirements:

Overall line configuration can be planned according to sheet thickness and downstream forming needs, allowing smooth integration between extrusion and forming processes.

Installation & Ongoing Support

The system supports remote monitoring and basic fault diagnostics. When operational issues occur, technicians can assist with remote checks, helping shorten troubleshooting time and reduce downtime risk.

After installation, operator training and basic maintenance guidance are provided. This allows operators to become familiar with settings and daily operation, enabling a smooth transition into production without relying entirely on on-site support.

Applicable Industries & Applications

-

Plastic cups, salad bowls, egg cartons, and compostable food trays.

-

Takeout containers, transparent lids, PLA food boxes, and cold drink packaging.

-

Clear egg cartons, fresh produce trays, and compostable packaging to improve presentation and freshness.

-

PLA and compostable materials for packaging processes aligned with EU and US sustainability standards.

-

Colored acrylic sheets, printed backing boards, and thermoformed display items.

-

Pharmaceutical trays and blister packaging requiring hygienic-grade materials.

-

Suitable for OEM and brand supply chains requiring multiple materials and product specifications.

Technical Specifications

| Item | Specification |

|---|---|

| Application Type | Designed for PET, PLA, PBAT vacuum forming sheets |

| Extrusion Technology | Single screw extrusion; supports multi-layer co-extrusion (main/sub extruder) |

| Compatible Materials | PET, PLA, PBAT; supports virgin and recycled materials |

| Sheet Thickness Range | 0.2–1.8 mm (adjustable) |

| Sheet Width Range | Customizable according to client requirements |

| Production Capacity | Approx. 200–1000 kg/hr |

| Control System | PLC with HMI interface and automatic temperature control |

| Power Requirement | Configured based on plant voltage (V, Hz, kW) |

| Machine Dimensions | Approx. 20m × 6m × 3m |

| Model | CT-110PET | CT-125PET | CT-150PET |

|---|---|---|---|

| Capacity | 250-300 kg/hr | 350-420 kg/hr | 500-600 kg/hr |

FAQ

Compared to conventional materials, PLA and compostable materials are more sensitive to temperature and process conditions. Stable equipment performance and clear settings are therefore important. With stable line conditions, consistent production can still be achieved.

No. The line can be configured to process PET, PLA, or compostable materials. Actual settings will be adjusted based on material properties and product requirements.

Not necessarily. The line can produce sheets independently. Whether to integrate downstream forming equipment depends on existing production lines and product requirements.

In most cases, a full line replacement is not required. Adjustments to settings and configuration can accommodate changes in materials or sheet specifications, making it suitable for evolving product plans.

Yes. Configuration can be adjusted based on factory space, power supply, and capacity requirements. Providing basic production information during inquiry helps ensure an appropriate setup.