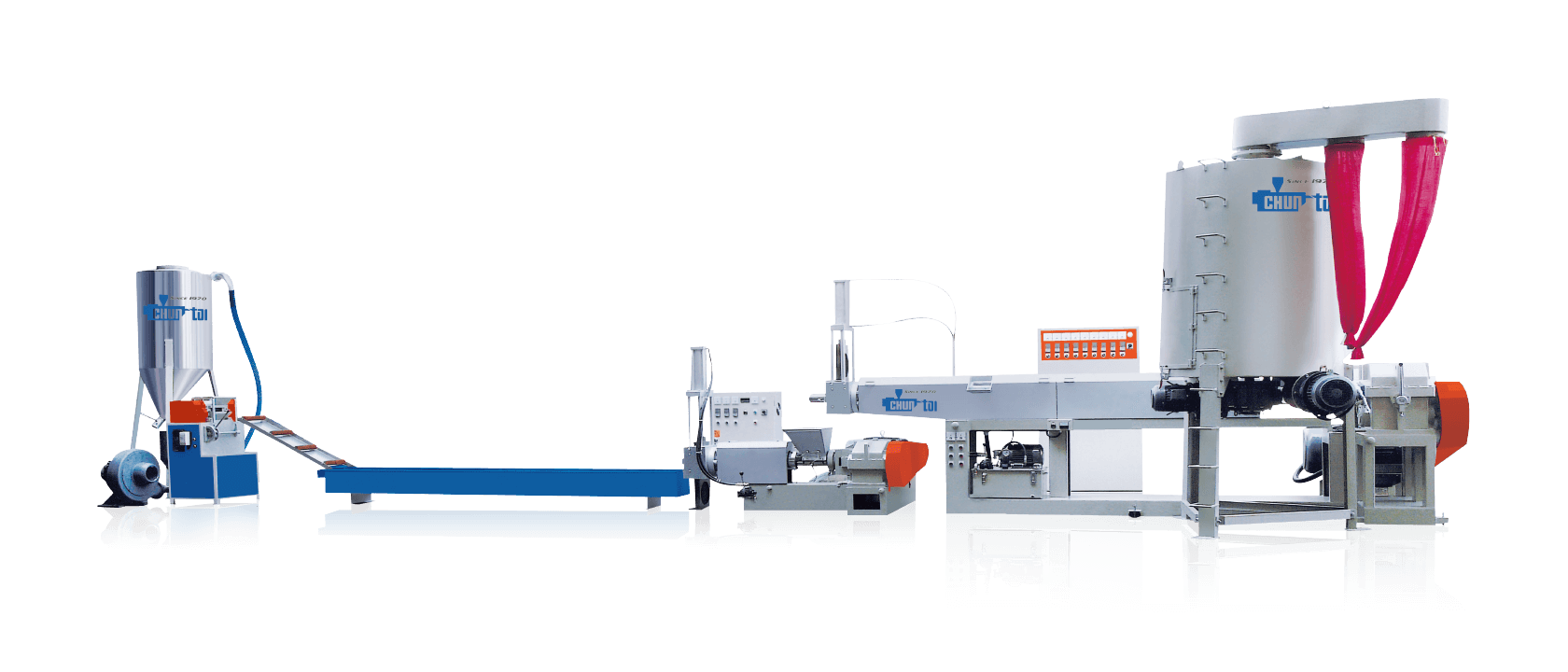

2 Stages Plastic Recycling Machine (Side Feeding)

Product Overview

The 2-Stage Plastic Recycling Machine (Side Feeding) is engineered to process complex plastic waste streams that are highly contaminated, high in moisture content, or difficult to handle. Featuring a side screw feeder, dual degassing zones, and a tandem (mother-baby) extrusion system, it is especially effective for recycling materials such as agricultural films, printed packaging, and woven sacks.

This system utilizes a strand pelletizing method with water bath cooling and air drying, making it particularly suitable for moisture-sensitive or impurity-laden materials that are not ideal for die-face cutting. A large-capacity buffer hopper enables continuous feeding with minimal operator involvement, ensuring smooth material flow and stable pellet output over extended production runs.

Key Features

- Side Screw Feeding System

Delivers consistent feeding of lightweight, low-bulk-density materials like thin films and foils. - Dual Degassing with Dual Filtration

Effectively removes moisture and ink from printed or wet film scrap, improving pellet purity. - Optional Vacuum Exhaust Module

Enhances venting efficiency for better moisture removal and gas release. - Strand Pelletizing with Water Bath Cooling + Air Drying

Designed for materials that are sensitive to moisture or not suitable for die-face pelletizing. - Customizable Screw & Feeding Configuration

Screw geometry and feeding parameters can be tailored to specific material properties. - High-Capacity Buffer Hopper

Supports longer operation cycles with reduced manual intervention and smoother feeding.

Applications

- Moisture-rich soft films such as LLDPE, HDPE, LDPE, and PP

- Printed packaging films, woven bags, and post-industrial film scrap

- Dusty, ink-contaminated, or unevenly dried materials

- Elastic or blended films unsuitable for die-face pelletizing systems

Technical Specifications

| Item | Specification |

|---|---|

| Standard Output | Approx. 800 kg/hr (depending on material condition) |

| Applicable Materials | LLDPE, HDPE, LDPE, PP (not suitable for PET) |

| Maximum Moisture Tolerance | Up to ~5% |

| Extrusion System | Two-stage (mother-baby) tandem extruders |

| Degassing | Dual venting zones; optional vacuum exhaust module available |

| Feeding Method | Side-mounted screw force feeding |

| Pelletizing Method | Strand cutting with water bath cooling and air drying |

| Filtration & Screen Change | Manual screen change; automatic switching not supported |

| Customization | Screw and feeder configurations adaptable to material type and behavior |