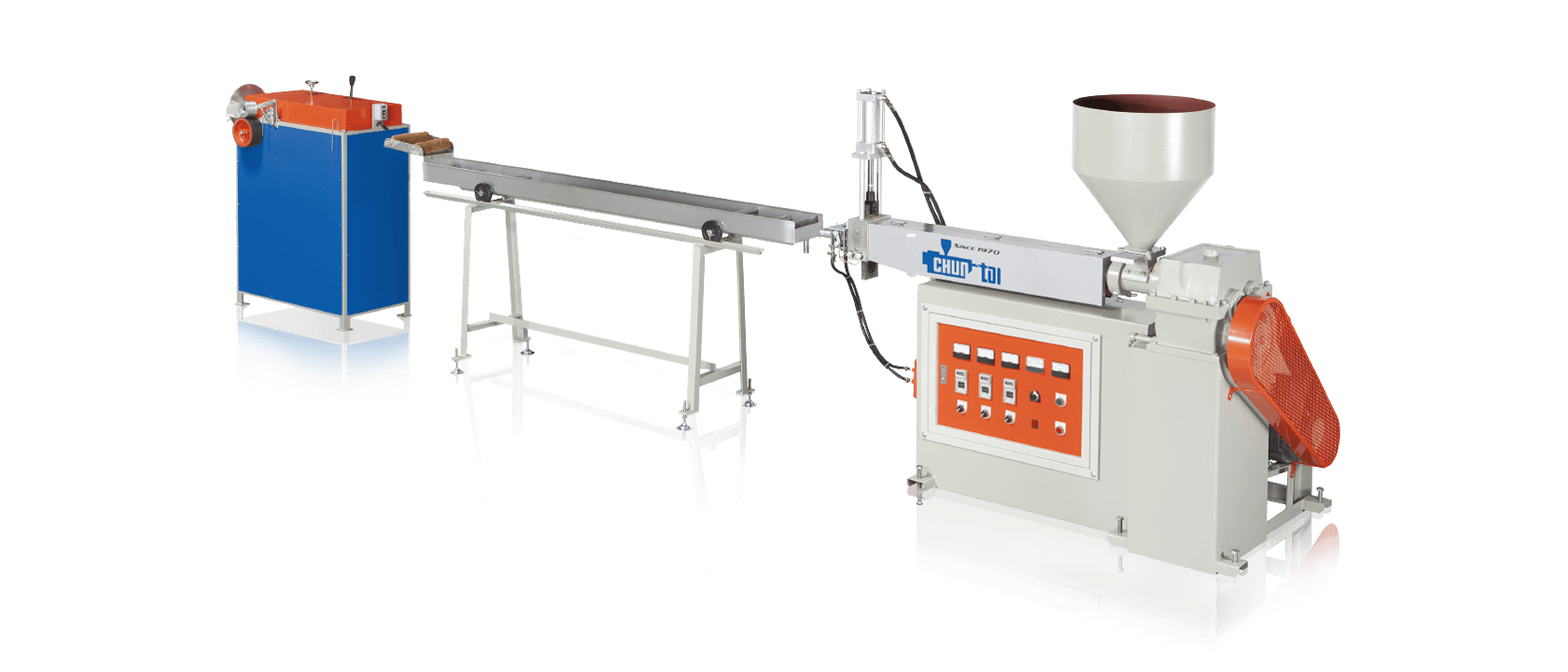

PP Mat Making Machine

Product Overview

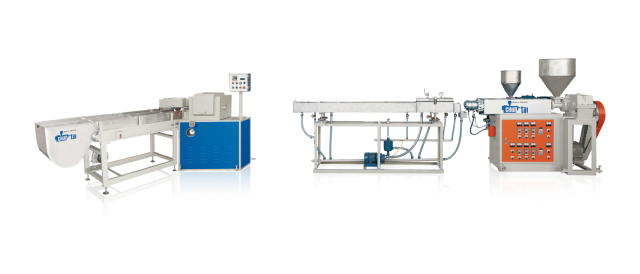

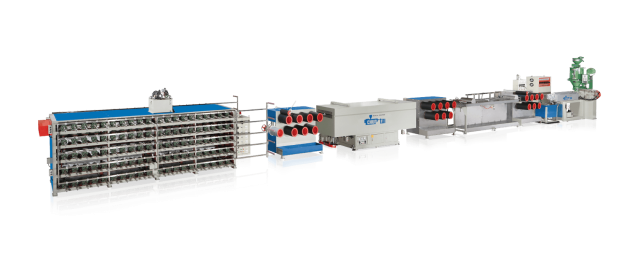

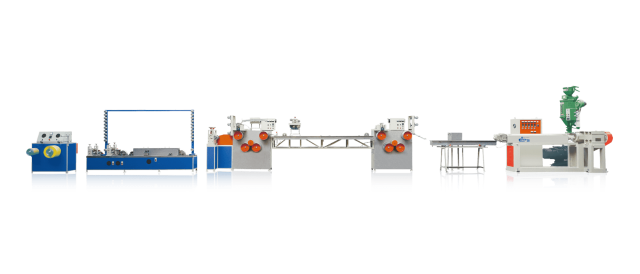

The PP Mat Making Machine is engineered for the efficient production of plastic strips used in prayer mats, woven mats, and cooling mats—particularly for export markets in the Middle East and Africa. This extrusion system delivers consistent output of flat PP strips in various widths and thicknesses and allows up to 50% recycled content, helping manufacturers balance performance, cost-efficiency, and sustainability.

Key Features

- Flexible Strip Length: 70–300 cm

Accommodates different mat formats and regional specifications with ease. - Recycled Material Compatibility (Up to 50%)

Supports a blend of virgin and recycled PP to reduce raw material costs. - Custom Embossing Patterns

Embossing rollers can be customized with motifs specific to target markets. - No Die Change for Size Switching

Strip width adjustments can be made without replacing the die head. - Optional Drying & Filtration Units

Enhance processing consistency, especially when using recycled materials.

Applications

- Religious Products: Prayer mats and woven mats for Islamic use

- Household & Daily Use: Cooling mats, picnic mats, and floor coverings

- Outdoor Utility: Temporary ground sheets and plastic grass mats

- Export Production: Tailored for high-demand markets in the Middle East and Africa

Technical Specifications

| Item | Specification |

|---|---|

| Strip Length Range | 70–300 cm (width and thickness fixed per design) |

| Output Capacity | 30–60 kg/hr (depending on strip thickness and material) |

| Material Compatibility | 50:50 blend of virgin and recycled PP |

| Die System | No die head change required for strip width adjustments |

| Cooling & Cutting | Inline setup; auto cutting not supported |

| Embossing Options | Customizable patterns for regional design preferences |

| Downstream Integration | Not compatible with automatic weaving or cutting modules |

FAQ

- Q1: Does using recycled PP affect product quality?

A1: When paired with drying and filtration units, recycled PP can be processed with consistent quality and output stability. - Q2: Do I need to change the die to switch strip sizes?

A2: No. Width adjustments can be made mechanically without replacing the die head. - Q3: Can this machine be linked to weaving or automatic cutting systems?

A3: This model is not designed for inline integration with weaving or downstream automation. - Q4: Are the embossing patterns customizable for different export regions?

A4: Yes. Embossing rollers can be tailored with designs that reflect cultural and market-specific aesthetics.