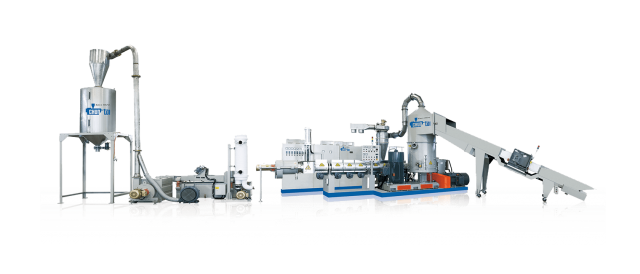

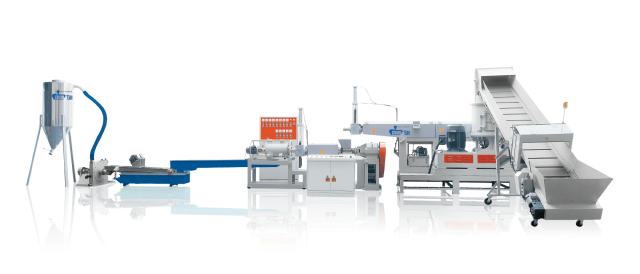

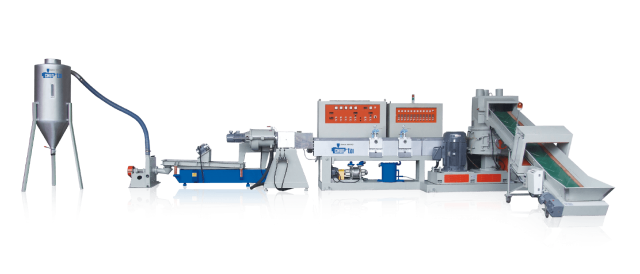

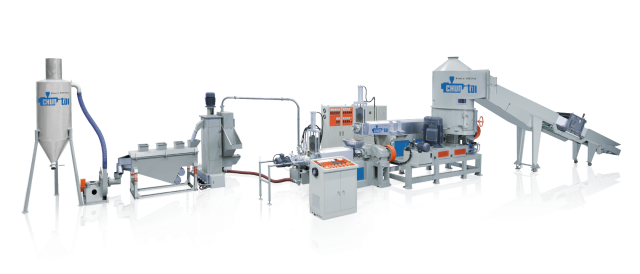

Plastic Grinder

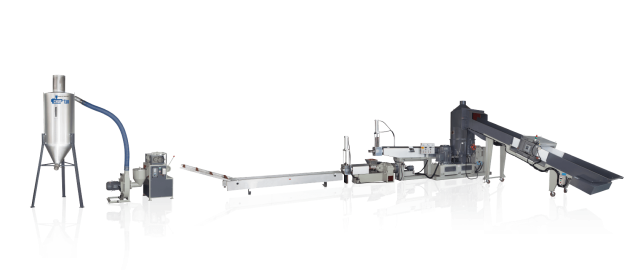

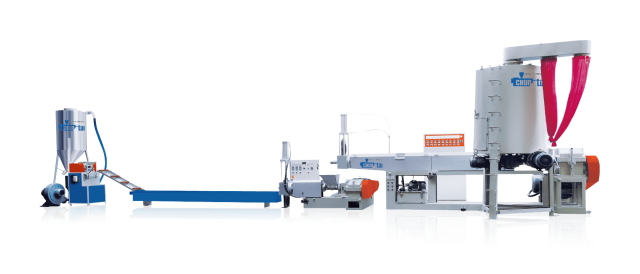

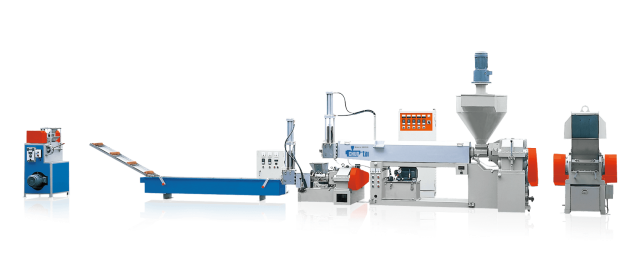

Product Overview

The Plastic Grinder is a high-throughput, heavy-duty crusher engineered for efficient size reduction of large and rigid plastic components. From everyday bottles and containers to oversized items like 20-gallon drums, the machine reliably processes a wide range of plastic waste.

Key components—including blades, screen meshes, and feeding/discharge modules—can be customized to match specific material properties and plant layout requirements. It’s ideal for centralized in-plant grinding, material classification, and pre-processing in recycling workflows.

The grinder supports both manual and automated material handling, and an optional soundproof enclosure is available to reduce operational noise. As a core unit in most recycling lines, it ensures consistent and scalable performance.

Key Features

- High-Throughput Grinding Capacity: Processes up to 1000 kg/hr, suitable for medium to large-scale recycling operations.

- Wide Material Compatibility: Capable of crushing sprues, large plastic blocks, PA drums, and glass fiber-reinforced materials.

- Customizable Blade System: Blade quantity and configuration (rotating and fixed) can be tailored to suit different plastics and hardness levels.

- Flexible Screen Options: Interchangeable screen meshes available from 12 mm to 100 mm to meet downstream particle size requirements.

- Optional Soundproof Enclosure: Minimizes operational noise to enhance operator comfort and reduce environmental impact.

- Modular Construction: Customizable infeed and discharge modules support both manual and automated integration.

Applications

- Crushing plastic bottles, containers, sprues, and bulky or rigid plastic parts

- Pre-processing stage in recycling lines for material size reduction and classification

- Shredding high-hardness or irregularly shaped engineering plastics

- Upstream preparation for extrusion or pelletizing systems

Technical Specifications

| Item | Specification |

|---|---|

| Throughput | Approx. 200–1000 kg/hr (depending on material properties) |

| Maximum Input Size | Customizable; capable of processing items up to 20-gallon drum size |

| Blade Configuration | Adjustable rotating and fixed blades according to material type |

| Screen Mesh Size | Selectable from 12 mm to 100 mm |

| Supported Materials | Buckets, PA, PP, PE, sprues, GF-reinforced plastics |

| Blade Maintenance | Quick-change blade design for fast maintenance |

| Noise Reduction | Optional soundproof enclosure available |

| Feeding & Discharge Modules | Customizable ports; supports integration with automated systems |

FAQ

- Q1: What types and sizes of materials can this machine process?

A1: It handles a variety of plastic containers, sprues, and large components. Inlet size can be customized to accommodate larger items such as drums. - Q2: Is the particle size adjustable?

A2: Yes. Particle size can be controlled by selecting the appropriate screen mesh, ranging from 12 mm to 100 mm. - Q3: Can it grind hard or fiber-reinforced engineering plastics?

A3: Yes. With the right blade configuration, it can process PA drums, GF-reinforced plastics, and other tough materials. - Q4: Are noise reduction features available?

A4: Yes. An optional soundproof enclosure helps reduce noise levels during operation. - Q5: Does the system support automation?

A5: Yes. Both feeding and discharge can be automated, with modules configurable to fit existing plant setups.