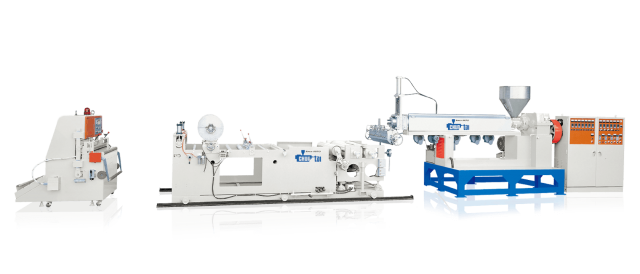

Plastic Crusher

Product Overview

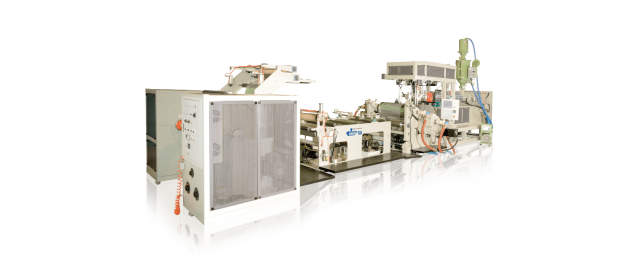

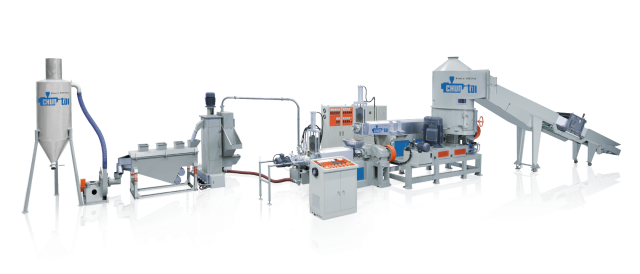

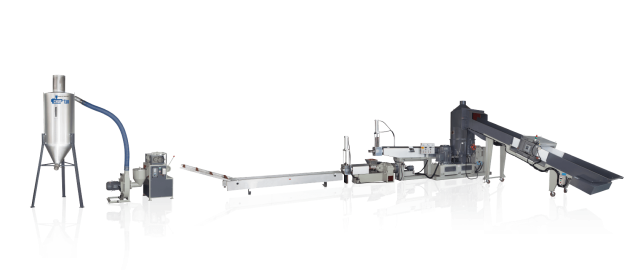

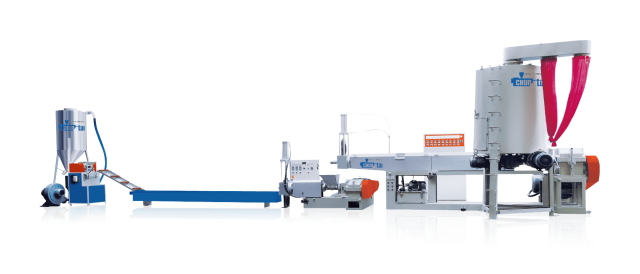

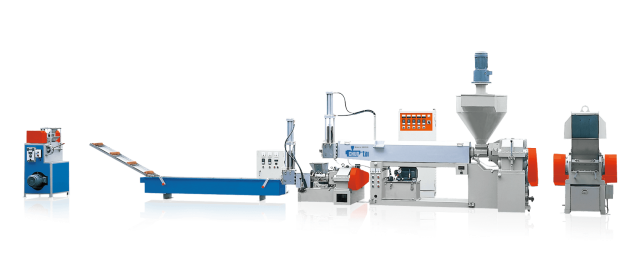

The Online Sheet Edge Crusher is specifically designed for vacuum forming production lines, enabling real-time processing of edge trim and scrap materials. While it is not a three-in-one system (crusher + extruder + pelletizer), it can be integrated inline with vacuum forming machines to enhance recycling efficiency without disrupting the main production flow.

Key Features

- Real-Time Crushing Design

Instantly crushes edge trim from vacuum forming to prevent material buildup and avoid secondary handling. - Inline Integration Support

Capable of connecting directly to vacuum forming equipment for a continuous recycling loop. - Simple Operation & Easy Maintenance

Compact and user-friendly design allows for convenient placement next to the production line for immediate use. - Recycling-Ready Output

Crushed materials can be directly fed back into the original production process for reuse.

Applications

Suitable for:

- Scrap trimming in vacuum forming processes

- Edge trim recycling in stationery sheet and food packaging sheet lines

- Sheet edge grinding in plastic extrusion lines

Not suitable for:

- Highly contaminated materials (e.g., post-wash films with ink residue or high moisture agricultural films)

- Three-in-one recycling applications (extrusion and pelletizing not included)

Technical Specifications

| Item | Description |

|---|---|

| Applicable Waste Types | Vacuum forming edge trim, sheet edge scrap |

| Suitable for Contaminated Materials | No; not suitable for washed, inked, or high-moisture materials |

| Recycling Method | Crushed into flakes; can be reused in the original production process |

| Inline Connection Support | Yes; can be connected to vacuum forming machines for inline recycling |

| Three-in-One Function | No; standalone crusher only |

| Twin Extrusion / Degassing / Filtering | Not supported |

| Max Processing Capacity | Not specified; actual output depends on material condition |

| Power Requirement | Based on site voltage; customizable per customer requirements |

FAQ

- Q1: What types of plastic waste does this crusher handle?

A: It is primarily used for crushing edge trim and scrap from vacuum forming processes. - Q2: Can it process post-washed or contaminated materials?

A: No, it is not suitable for materials with high moisture, ink, or other contaminants. - Q3: Can the crushed material be reused directly?

A: Yes, the recycled flakes can be sent back to the production line for reprocessing. - Q4: Is this a three-in-one integrated machine?

A: No, it is a standalone crusher with no extrusion or pelletizing functions. - Q5: Can it be connected to the production line?

A: Yes, it supports inline connection with vacuum forming machines. - Q6: Does it support twin extrusion or dual filtration?

A: No, these functions are not included. - Q7: What is the maximum capacity?

A: There is no fixed specification; capacity depends on the type and condition of the material.

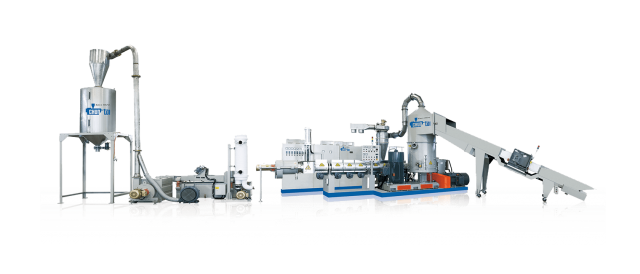

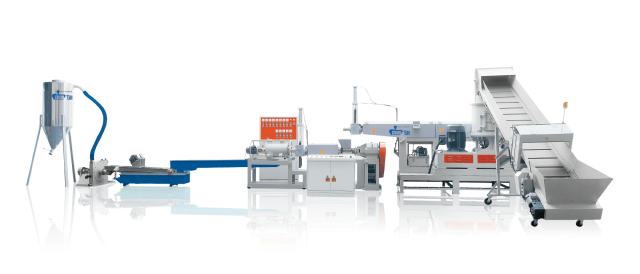

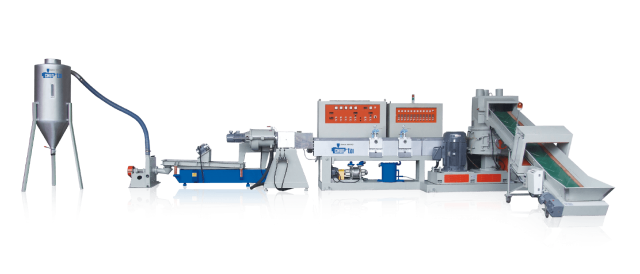

Related Products