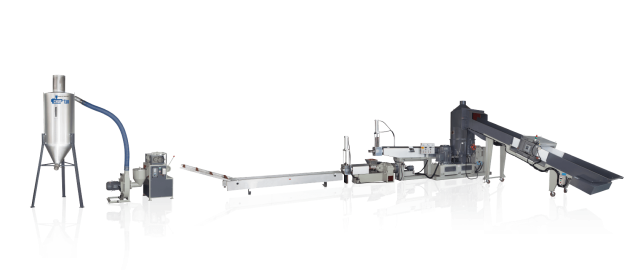

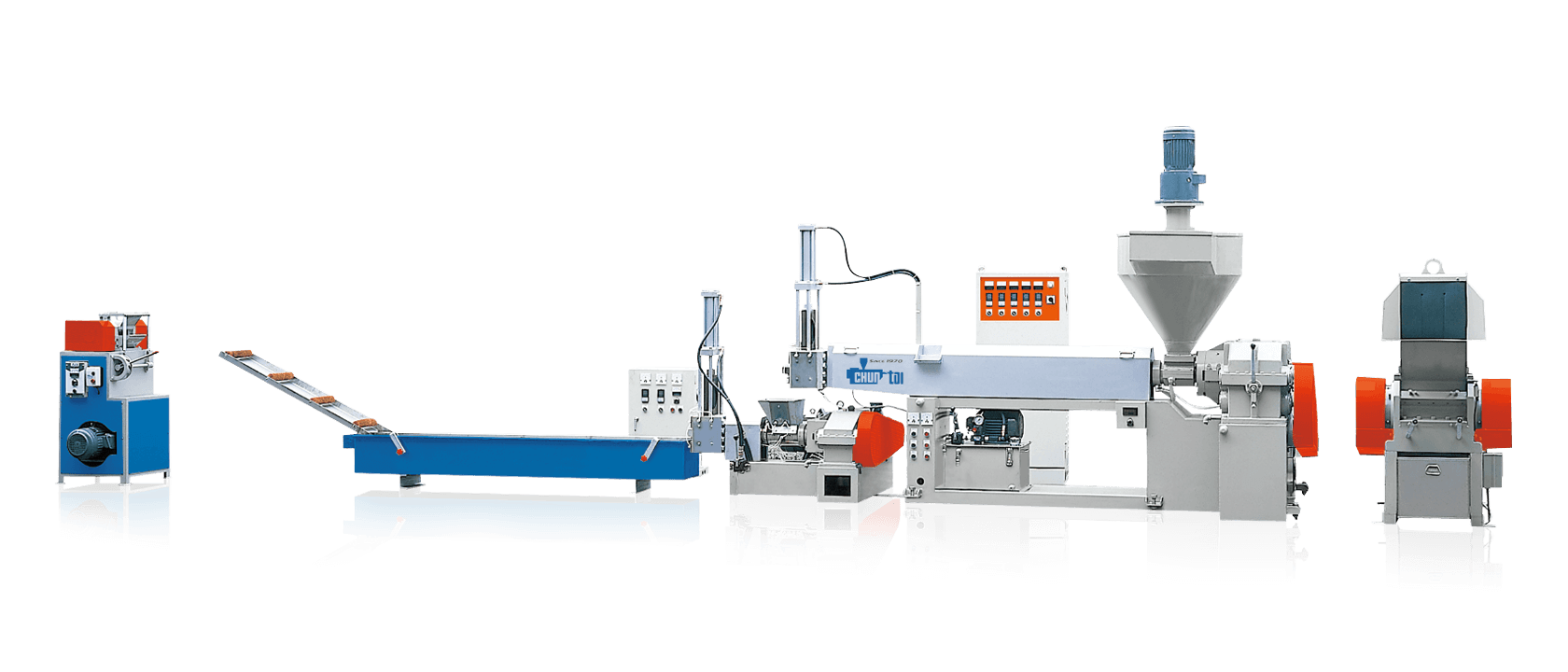

2 Stages Plastic Recycling Machine (Force Feeding)

Product Overview

The 2-Stage Plastic Recycling Machine (Force Feeding) is designed to handle general film recycling as well as materials with moderate to heavy contamination. Built on a traditional force feeding system, it features a two-stage (mother-baby) extrusion line equipped with dual degassing zones. The machine ensures consistent material intake without the need for a side feeder, making it an excellent solution for upgrading existing lines or expanding plant capacity.

This system utilizes a strand pelletizing process with water bath cooling and air drying—particularly effective for printed films or materials containing dust, paper, or adhesives. Dual-stage extrusion combined with a dual-screen filtration setup ensures efficient removal of moisture and impurities, resulting in high-quality pellets that are compatible with downstream processing.

Key Features

- Traditional Force Feeding System: Ideal for high-density, low-bulk-flow materials such as compacted film flakes or regrind.

- Two-Stage Extrusion with Dual Degassing Zones: Improves gas evacuation and melt stability for better pellet quality.

- Strand Pelletizing with Water Cooling & Air Drying: A compact and reliable method for moisture-sensitive or printed materials.

- Optional Upgrades: Vacuum Venting, Conveyors, Auto Baler: Add-on modules support automation, improved venting, and streamlined material handling.

- Manual Screen Changer (Quick-Change Option Available): Offers simple filtration maintenance with upgrade paths for higher efficiency.

- Modular, Space-Efficient Design: Easily fits into standard production layouts while allowing future line expansion.

Applications

- Printed packaging films, food-grade film scraps, and woven bags

- Mixed plastic waste containing paper fibers, dust, or inconsistent contaminants

- Standard recycling operations that do not require side feeding systems

- Mid- to high-volume pelletizing lines requiring flexibility and modularity

Technical Specifications

| Item | Specification |

|---|---|

| Output Capacity | Approx. 100–800 kg/hr (based on material condition) |

| Applicable Materials | HDPE, LLDPE, LDPE, PP, printed films, composite films |

| Feeding System | Traditional force feeding |

| Extrusion Design | Two-stage (mother-baby) tandem extruders |

| Degassing | Dual venting zones; optional vacuum degassing available |

| Filtration System | Dual-screen die head; manual operation (optional quick-change upgrade) |

| Pelletizing Method | Strand cutting with water bath cooling and air drying |

| Line Integration | Compatible with conveyors, auto-packaging units, and water cooling systems |

| Optional Modules | Metal detector, odor removal unit, material storage tank (customizable) |